Description

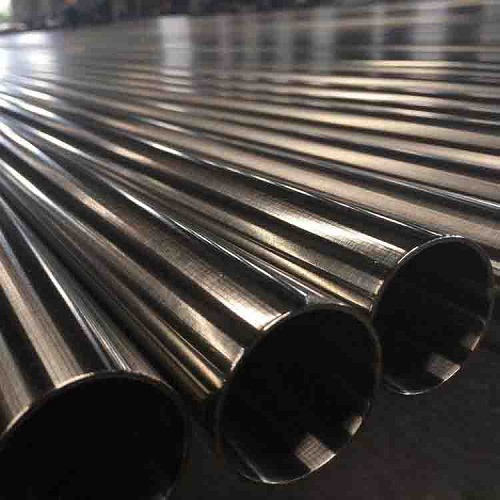

| Product name: | AISI ASTM 8 inch 316 stainless steel pipe |

| Certification: | ISO |

| Color: | Silver or custom |

| Shape: | Round, Square, etc |

| Length: | 6 – 15 M or as customer requirements |

| Outer Diameter: | 2.5mm-2300mm |

| Supply Ability: | 8200 Ton Per Month |

| Brand Name: | Sino East |

Some chemical composition reference of stainless steel pipe:

|

Grade

|

C

|

Si

|

Mn

|

P

|

S

|

Ni

|

Cr

|

Mo

|

|

201

|

≤0 .15

|

≤0 .75

|

5. 5-7. 5

|

≤0.06

|

≤ 0.03

|

3.5 -5.5

|

16 .0 -18.0

|

–

|

|

202

|

≤0 .15

|

≤l.0

|

7.5-10.0

|

≤0.06

|

≤ 0.03

|

4.0-6.0

|

17.0-19.0

|

–

|

|

301

|

≤0 .15

|

≤l.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

6.0-8.0

|

16.0-18.0

|

–

|

|

302

|

≤0 .15

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

8.0-10.0

|

17.0-19.0

|

–

|

|

304

|

≤0 .0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

8.0-10.5

|

18.0-20.0

|

–

|

|

304L

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

9.0-13.0

|

18.0-20.0

|

–

|

|

309S

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

12.0-15.0

|

22.0-24.0

|

–

|

|

310S

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.035

|

≤ 0.03

|

19.0-22.0

|

24.0-26.0

|

|

|

316

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

10.0-14.0

|

16.0-18.0

|

2.0-

3.0 |

|

316L

|

≤0 .03

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

12.0 – 15.0

|

16 .0 -1 8.0

|

2.0 –

3.0 |

|

321

|

≤ 0 .08

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

9.0 – 13 .0

|

17.0 -1 9.0

|

–

|

What are the differences between 304 and 316 stainless steel? Stainless steel pipe suppliers to give detailed introduction:

1. The chemical composition is different: 304 is a cover stainless steel, its material composition is 0Cr18Ni9, 316L is an austenitic stainless steel, and the material composition is 00Cr12Mo2Ti.

2. Different properties: 304 steel is resistant to corrosion by sulfuric acid, phosphoric acid, formic acid, urea, etc. It is suitable for general water, controlled gas, wine, milk, CIP cleaning fluid and other occasions with little corrosion or no contact with materials.

3. The addition of molybdenum element to the 3.316L steel grade on the basis of 304 can significantly improve its ability to resist intergranular corrosion, oxide stress corrosion and reduce the tendency of hot cracking during welding. It also has good resistance to chloride corrosion. Because of the molybdenum element and nickel element added in 316, 316 stainless steel is more expensive than 304 stainless steel.

4. Corrosion resistance: 316 stainless steel is 304 stainless steel with some molybdenum added to resist pitting corrosion. In various types of water quality (distilled water, drinking water, river water, boiler water, etc.), 304 stainless steel and 316 stainless steel have almost the same corrosion resistance, but when the content of chloride ion in the medium is very high, 316 stainless steel is more suitable.

5. Different maintenance methods: 304 has better corrosion resistance, oxidation resistance and workability than 316 stainless steel.