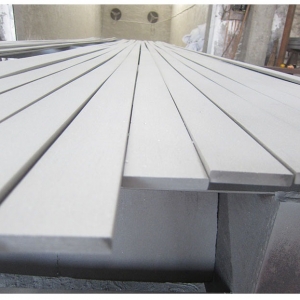

Flat Bar

Sino East Steel, a top steel products’ manufacturer and exporter in China, is specialized in producing a wide variety of products of steel such as main categories in steel sheets, steel pipes, steel profiles (structural steel) and steel wires (iron wire). meanwhile, Flat bar as one kind of structural steel is widespread to apply to kinds of industries and the steel flat bar the company manufactured always are popular for the steel buyers from home and abroad. Simply understanding about flat bar steel is a flat and rectangular section with right-angle edge in demand size, in meantime, the length of steel flat bar is depended on the requirement of customers. The maximum length we may produced is up to 144.0”.

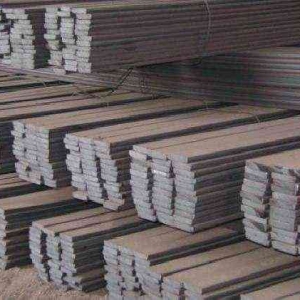

Difference between Flat bar and Steel plate

- The main difference for both of flat bar and steel plate is about technology craft. The flat bar steel belongs to structural steel such as angle bar and steel channel, etc. with molding method of hot rolled and cold drawn. Its hot rolled flat bar is width with max 150mm, and thickness with max 60mm. However flat bar’s edge is circular arc.

- The flat bar steel is widely used. It looks like a slab cut from a common steel plate, but it is actually hot rolled. The edge of flat steel is called rolling edge. Rolling edge guarantees the strength of its edge.

Specification of Flat Bar

The flat bars, Sino East Steel produced, are match to international standard such as ASTM A36, JR S355 and EN 10025, etc. About its size will be listed below,

Thickness: 0.1875″ Width: 6.0″

Thickness: 0.375″ Width: 2.5″

Thickness: 0.125″ Width: 5.0″

Thickness: 1 Width: 1.25″

Thickness: 1.5″ Width: 3.5″

Thickness: 0.125″ Height: 16.0″

Thickness: 0.3125″ Height: 22.0″

Thickness: 0.625″ Width: 1.0″

Thickness: 2.5″ Width: 3.0″

Thickness: 0.75″ Width: 2.25″

Thickness: 1.75″ Width: 2.0″

Thickness: 1.75″ Width: 2.5″

Thickness: 0.625″ Width: 6.0″

Thickness: 0.25″ Width: 0.375″

Thickness: 0.25″ Width: 0.75″

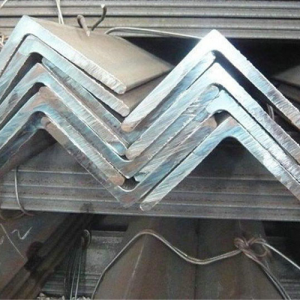

Use of Flat Bar

Actually Flat bar products are widely and professionally applied on manufacturing industry of steel structure, mechanical manufacture, automobile industry, Mine machinery and hoisting machinery, etc. According to its hot rolled and cold drawn process, we may consider its uses such as

- Hot rolled flat bar steel

- It may use for construction members, staircases and fences, etc. The hot rolled flat bar features smoother surface, good weldability, stronger load capacity, etc, so it is met to requirement of construction members, fences and staircases products.

- Hot rolled flat steel can be used as the billet of welded steel and the slab of pack-rolled sheet.

- The hot rolled flat steel could finish and produce about hoop iron because of its rectangle shape, good flexibility, variety of specification of width and length.

- Cold rolled flat bar steel

The cold rolled or cold drawn flat bar meets to steel property and good surface evenness, so it is well used in machine tool building, hydroelectric facility manufacturing, fabrication of wood-working machine, home appliances, office equipment, instrument and meters, construction machinery, standard parts, steel furniture and crafts, fitness facilities, hardware industry, aviation, etc.

Advantage of Steel Flat Bar

- The surface clean. The flat bar steel with the process of adopting high pressured water for descaling ensures smooth and clean of surface of steel flat bar.

- The steel flat bar is made by negative deviation rolling, however it is delivered as actual weights. So the rate of uses is higher as 1 to 5 percentage than steel plates’.

- It could be manufactured according to the customers’demand, with fixed thickness, width and lengths. Meanwhile, reducing the cutting method and saving the time and process for customers; lower the consumption of labors and materials as time-saving, labour-saving and material-saving; avoid the process loss of row materials.