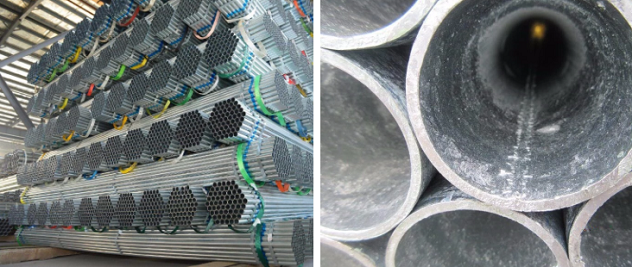

Galvanized steel pipes are divided into hot-dip galvanizing and cold-galvanizing. Hot dip galvanizing is the process of immersing the tube in a high temperature zinc bath to allow zinc to penetrate the surface of the steel. The surface of the pipe has a thick zinc layer and corrosion resistance higher than that of cold-dip galvanizing. Of course, the price is also higher than that of cold-dip zinc. In fact, cold-dip zinc is an electro-galvanized pipe. A layer of zinc adheres to the surface of the tube by electroplating chemical reaction, but the zinc layer is thin and easily falls off. The price is cheaper. Both prices are higher than ordinary steel pipes. After special spraying on the surface of galvanized pipes, the anti-corrosion performance is dozens of times higher than that of iron pipes.

Ordinary steel pipe is less resistant to corrosion than galvanized steel pipe. Zinc plating refers to the surface of steel pipes being galvanized. It may be welded pipes or seamless pipes. Seamless refers to the manufacturing process of steel pipes, with welding and no Sewing points. Galvanized pipes are resistant to corrosion and seamless pipes can withstand higher pressures.Galvanized steel tubes are not easy to rust due to zinc protection. Galvanized tubes are lighter than seamless pipes. If it is used for balconies, it is best to use galvanized light pipes. Seamless steel pipe is not suitable for balcony. Because the seamless steel tube wall thickness, the natural weight is heavy, and the cost of the seamless steel pipe is higher than the cost of the galvanized pipe, and the galvanized tube is very durable, and the service life is far more than the seamless pipe. If the quality is too good, it should not be a problem for more than 20 years. Of course, the welding and paint should be done well, and it will not affect the service life of the galvanized steel pipe.

The main differences between galvanized steel pipes and general steel pipes are:

1. Manufacturing process: Galvanized steel tubes and ordinary steel pipes are two categories of steel pipes. Zinc plating means that the surface of steel pipes is galvanized, and ordinary steel pipes are not.

2, Use: galvanized steel pipe is generally used to do fences, fences, guardrails and so on. Widely used in municipal engineering, roads, factories, schools, development zones, gardens, plazas, residential areas and other places. Ordinary steel pipes are now basically replaced by galvanized steel tubes.

3, Durability: galvanized pipe is more resistant to corrosion, ordinary steel can withstand higher pressure. Galvanized steel pipes are not easy to rust due to the protection of zinc, and lighter than ordinary steel pipes.