Description

| Product Name : | Z60/z180 galvanized steel coil/sheet with reasonable cost zinc coating |

| Type : | Steel Coil |

| Thickness : | 0.1-1.76mm or as demands |

| Width : | 24mm to 1300mm or as demands |

| Zinc Coating : | 28-282g/m2 or as demands |

| Coil Weight: | 3-9MT/Coil or as your request |

| Length : | As requirememts |

| Certification : | ISO,SGS |

| Application : | Boiler Plate |

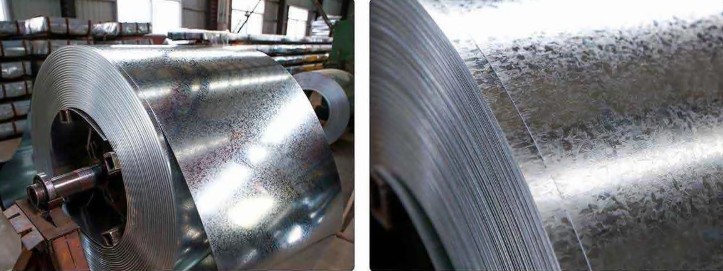

The galvanized steel coil is electrogalvanized to prevent rust, as rust does not corrode this protective metal. For countless outdoor, marine or industrial applications, galvanized steel is an essential manufacturing component. The primary method of making steel resistant to corrosion is to alloy it with another metal zinc. When the steel is immersed in molten zinc, the chemical reaction permanently bonds the zinc to the steel by galvanizing. Therefore, zinc cannot be used as a sealant completely like paint because it can coat not only steel. It actually becomes a part of it permanently.

The categories of galvanized:

1. Hot dip galvanizing: The main method of galvanizing the surface of the steel sheet is hot dip galvanizing.

2. Cold galvanizing: also known as electroplating zinc: the oil, acid washing liquid is removed, and then placed into the zinc salt solution by electrolysis equipment, and connected to the negative electrode of the electrolysis equipment, the zinc plate is placed at the positive electrode of the electrolysis device When opened, the cold-coated pipe is treated and then galvanized by the directional movement of current from the positive electrode to the negative electrode.

3. Mechanical galvanizing: In a drum equipped with plated parts, glass balls, zinc powder, water and accelerator, the glass ball as the impact medium rotates with the drum, thereby generating friction on the surface of the plated part. Hammered. Mechanical physics can “cold” the galvanized powder onto the surface of the coated part under the action of a chemical accelerator to form a smooth, uniform, fine coating with a certain thickness.