Discover the intricate process behind Sino East’s seamless steel pipe manufacturing. From raw materials to the final product, this article provides insights into the steps, technologies, and quality control measures that contribute to Sino East’s reputation as a top manufacturer.Seamless steel pipes are crucial components in various industries, popular for their strength and durability. Sino East’s manufacturing process exemplifies precision and excellence.

Introduction:

Sino East has established itself as a prominent player in the seamless steel pipe manufacturing industry. Next let’s delve into the key stages of sino east seamless steel pipe manufacturing process, showcasing their commitment to producing high-quality pipes.

Raw Material Selection and Inspection:

At the heart of Sino East’s process is the careful selection of raw materials. High-quality steel billets choose for their specific properties. Thus rigorous inspections conduct to ensure they meet industry standards. Preventing any compromises in the final product’s quality.

Heating and Piercing:

The selected steel billets undergo heating to a precise temperature that allows for seamless piercing. Additionally, this piercing process involves the creation of a hollow shell, setting the foundation for the pipe’s shape and structure.

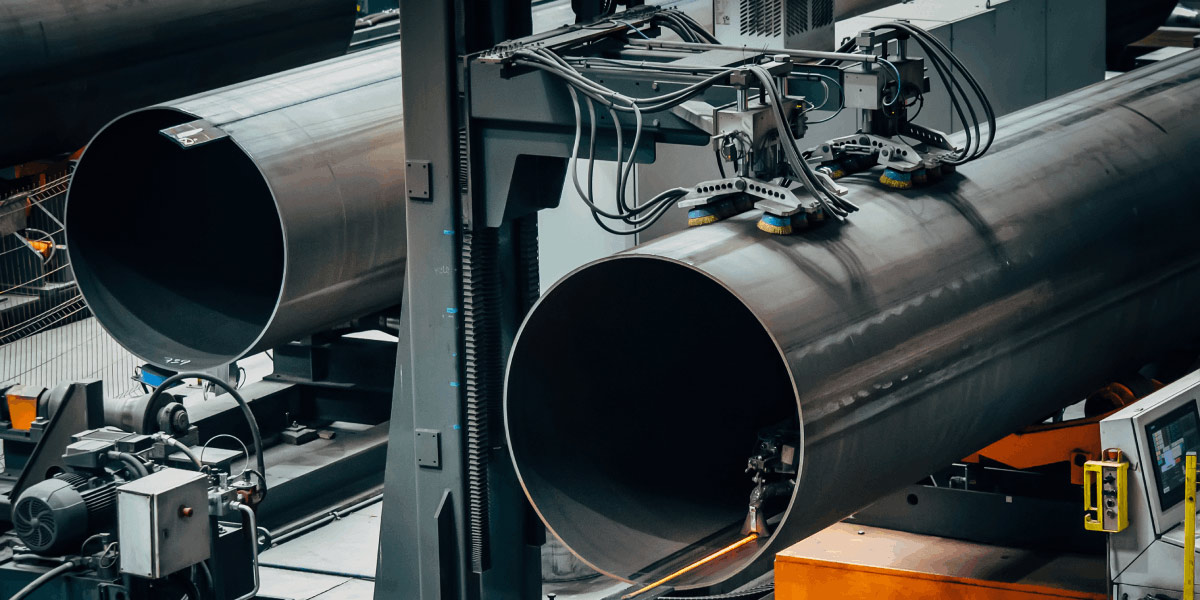

Hot Rolling and Sizing:

The hollow shell then goes through hot rolling, a process that refines the shape and dimensions of the pipe. Through multiple stages of rolling and sizing, the pipe achieves its desired dimensions with consistent thickness and diameter.

Heat Treatment:

Due to enhance the mechanical properties of the pipe, heat treatment employing. This process involves controlled heating and cooling, imparting strength and toughness to the material. Additionally, Sino East’s advanced heat treatment techniques ensure optimal pipe performance.

Cold Drawing and Cold Rolling:

The pipe further refines through cold drawing and cold rolling. These processes enhance dimensional accuracy and surface finish while improving mechanical properties. The result is a seamless steel pipe with precise specifications.

Cutting and Finishing:

The pipes are cut to the desired lengths, and both ends are finished to meet specific requirements. Sino East pays meticulous attention to detail during this stage, ensuring smooth edges and precise measurements.

Quality Inspection and Testing:

Before the pipes are ready for distribution, they undergo comprehensive quality inspections and testing. These tests include dimensional checks, visual inspections, and mechanical property assessments. Any pipes that do not meet Sino East’s stringent standards are discarded.

Final Packaging and Delivery:

Approved pipes are carefully packaged to prevent damage during transportation. Sino East ensures that the pipes reach their destination in optimal condition, ready to serve their intended purposes.

Conclusion:

In conclusion, the Sino East seamless steel pipe manufacturing process is a testament to precision, innovation, and quality. From the selection of raw materials to the final product delivery, each stage executes meticulously to produce seamless steel pipes that meet and exceed industry standards. Additionally, Sino East’s commitment to excellence has solidified its position as a trusted manufacturer in the competitive world of seamless steel pipes.