When it comes to choosing between seamless steel pipe and welded steel pipe, there are several factors to consider, including cost, strength, and durability. Both types of pipes have their advantages and disadvantages, depending on the specific application. This article provides an overview of seamless steel pipe vs welded and highlights the benefits and drawbacks of each type.

Introduction:

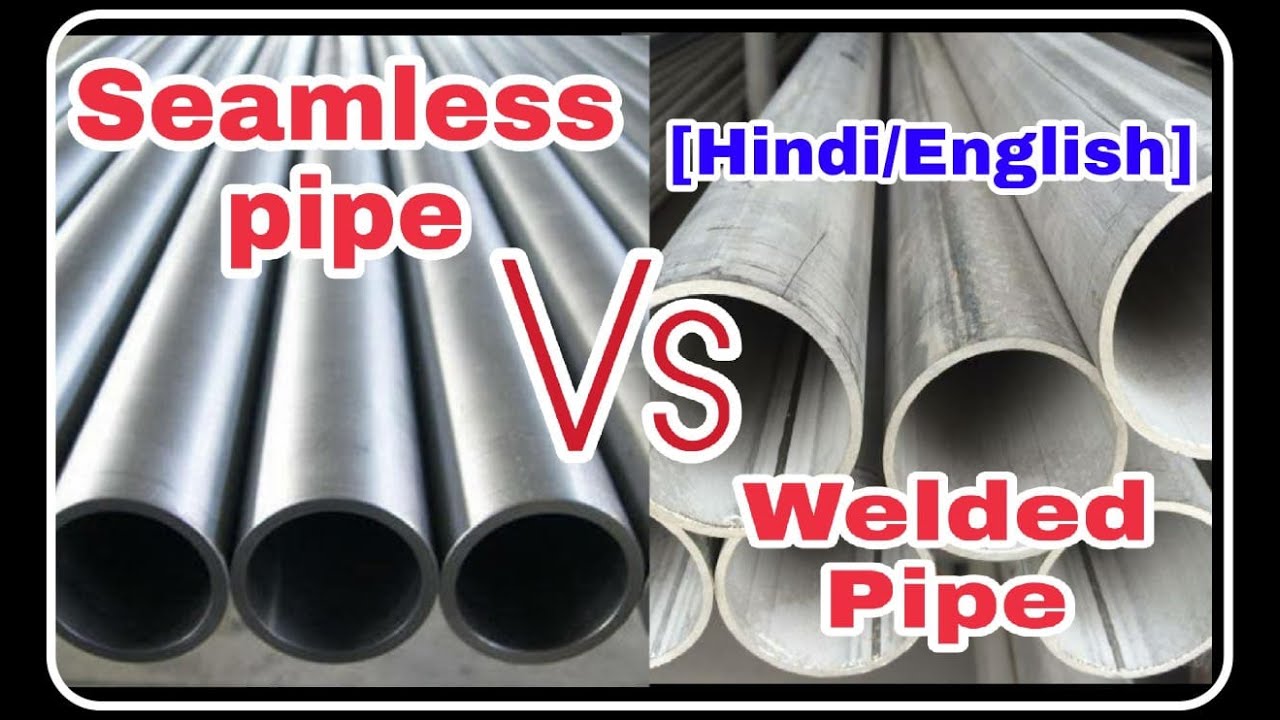

Steel pipes play an important role in various industries, including construction, oil and gas, and manufacturing. When it comes to selecting a steel pipe, the choice often comes down to seamless steel pipe vs welded. Seamless steel pipes making from a single piece of metal, while welded steel pipes are made by welding several pieces together. Each type of pipe has its advantages and disadvantages, depending on the specific application. This article aims to provide an overview of seamless steel pipe vs welded and highlight the benefits and drawbacks of each type.

What is a Seamless Steel Pipe?

Seamless steel pipe is a type of steel pipe which makes from a single piece of metal with no seams or joints. The process of manufacturing seamless steel pipes involves heating a steel billet to a high temperature and then piercing it with a mandrel to create a hollow tube.

What is Welded Steel Pipe?

Welded steel pipe is a type of steel pipe that is made by welding several pieces of steel together. The process of manufacturing welded steel pipes involves rolling a sheet of steel into a tube shape and then welding the edges together. However, they may be weaker than seamless pipes and may not be suitable for high-pressure or high-temperature applications.

Benefits and Drawbacks of Seamless Steel Pipe:

- Strength: Seamless steel pipes are popular for their strength and durability, making them ideal for high-pressure and high-temperature applications.

- Smooth Interior: Seamless steel pipes have a smooth interior surface, which reduces friction and allows for a more efficient flow of materials.

- Availability: Seamless steel pipes may be harder to find than welded pipes.

Benefits and Drawbacks of Welded Steel Pipe:

- Cost: Welded steel pipes are generally less expensive than seamless pipes, as they can be produced in large quantities.

- Weld Quality: Welded steel pipes may have a weaker weld seam, which can lead to leaks or failures over time.

Which is Better for Your Project?

When it comes to choosing between seamless steel pipe vs welded, it ultimately depends on the specific application. If strength and durability are the main concerns, then seamless steel pipes may be the better choice.

In conclusion, both seamless steel pipe and welded steel pipe have their benefits and drawbacks. Seamless steel pipes are famous for their strength and smooth interior. While welded steel pipes are more cost-effective and versatile. When choosing between the two, it’s important to consider the specific requirements of your project and consult with a professional to determine which type of pipe best suits your needs.