Description

| Product name: | A106 ERW spiral carbon 20 foot 4 inch hot finished welded tubes |

| Standard: | JIS, BS, DIN, API, ASTM, GB |

| Surface: | Black painted |

| Color: | Black, or as customer requirements |

| Material: | Q195/Q215/Q235/Q345 |

| Section Shape: | Round |

| Surface Treatment: | Transportation pipeline |

Welded steel pipes can be roughly divided into three categories according to the forming process:

1. Resistance welded steel pipe

Resistance welding steel pipe, English name ERW (Electric resistance welded Pipe), the weld type is straight seam. Resistance welding is a pressure welding method without filler metal. The welding seam is not filled with other components. The skin effect and proximity effect of high-frequency current cause the edge of the board to be heated to the welding temperature instantaneously. Organization of the weld.

Resistance welded steel tubes can be divided into two categories: HFW (High frequency welded pipe) and LFW (Low frequency welding).

ERW steel pipes are mainly used to transport oil, natural gas and other vapor-liquid objects, and can meet various requirements of high and low pressure. Currently, they occupy a pivotal position in the field of transportation pipes in the world.

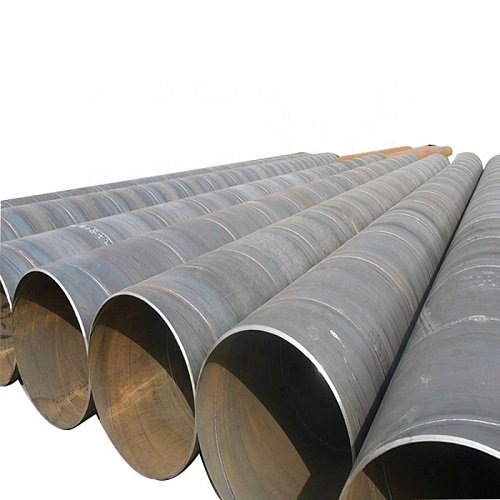

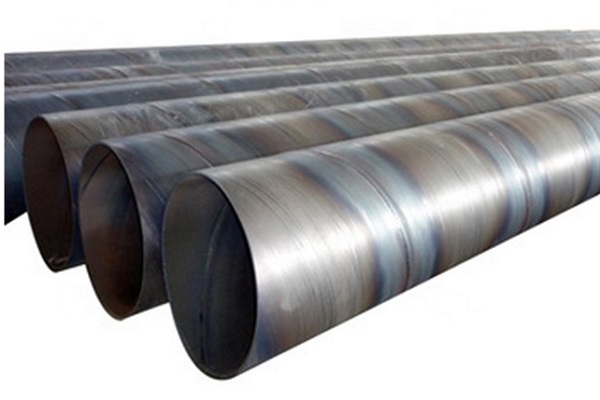

2. Spiral welded steel pipe

Spiral welded steel pipe, English name SSAW (Spiral submerged-arc welding pipe), the weld type is spiral seam. Submerged arc welding method, double-layer welding inside and outside. Submerged arc welding (including submerged arc surfacing and electroslag surfacing, etc.) is an important welding method, which has the inherent advantages of stable welding quality, high welding productivity, no arc light and little smoke and so on.

Spiral welded pipe is manufactured with a large diameter and can reach more than 3000mm, which is more suitable for large-diameter pipeline transportation and building structures.

3. Straight seam welded steel pipe

Straight seam welded steel pipe, English name LSAW (Longitudinally Submerged Arc Welded Pipe), the weld type is straight seam. The submerged arc welding method is also used, and the inner and outer double-layer welding. Straight seam steel pipe is manufactured with a large wall thickness, and its use is similar to spiral welded pipe.

Straight seam welded steel tubes can be divided into two categories according to different forming processes: UOE (Uing and Oing forming pipe) and JCOE (J-ing, C-ing and O-ing pipe). UOE forming method (U forming, O forming, E expanding diameter), JCOE forming method (steel plate is pressed into J type, and then pressed into C type and O type, and then expanded).