Steel structures, as an important structural form in modern construction, have been widely used in various engineering projects due to their unique performance advantages. This article will systematically introduce the main types of steel structure products and elaborate on their application scenarios in different fields, with special emphasis on professional applications in the petroleum industry, helping readers fully understand the technical characteristics and practical value of steel structures.

Main Types of Steel Structure Products

Steel structure products can be divided into several major types based on their structural form and functional characteristics:

1. Light Steel Portal Frame Structure

The light steel portal frame structure is one of the most commonly used steel structure forms in small and medium-sized buildings. Its core construction consists of a portal frame (H-shaped steel beam-column rigid connection nodes), purlin system (C/Z-shaped steel), and bracing system, forming a plane force-bearing system. This structure adopts variable cross-section design, where the beam-column cross-sections are optimized according to internal force changes, achieving efficient material utilization. The roof and walls use lightweight profiled steel plates (self-weight only 0.1-0.3kN/m²), reducing foundation loads by 40%-60% compared to concrete structures.

Light steel portal frame structures are suitable for industrial buildings (lightweight factories, warehousing logistics) and commercial facilities (exhibition halls, garages) with single spans of 20-30 meters and eaves heights within 10 meters. Typical projects include JD Logistics warehouses and small and medium-sized enterprise production workshops, with construction cycles of only 4-8 weeks and costs 20%-30% lower than concrete structures.

2. Steel Frame Structure

The steel frame structure consists of steel columns (H-shaped steel/round steel pipes) and steel beams (H-shaped steel/composite beams) connected through rigid nodes (fully welded/bolted-welded hybrid connections), forming a space force-bearing system that can achieve large column spacing of over 9 meters (such as the 8.4-meter column grid commonly used in office buildings). By combining hinged nodes with bracing systems, it can flexibly adapt to different seismic fortification requirements (up to meeting 8-degree seismic fortification).

Steel frame structures are widely used in multi-story commercial buildings (5-15-story office buildings), industrial buildings (heavy-duty factories), and seismic-resistant buildings. Their high ductility makes them the preferred structure in earthquake-prone areas (such as Sichuan, Japan).

3. Truss Structure

A truss is a structure composed of members connected by hinges, unique for its plane or space structure formed by straight members arranged in triangular units. This design allows the members to mainly bear axial tension or pressure, fully utilizing the material’s strength. Compared to solid-web beams, trusses can significantly save materials, reduce self-weight, and increase stiffness in larger spans.

There are various types of trusses, including steel trusses, reinforced concrete trusses, and prestressed concrete trusses, widely used in various buildings and engineering projects. Based on their shapes, trusses can be classified as triangular, trapezoidal, polygonal, parallel chord, and open-web trusses.

4. Space Frame Structure

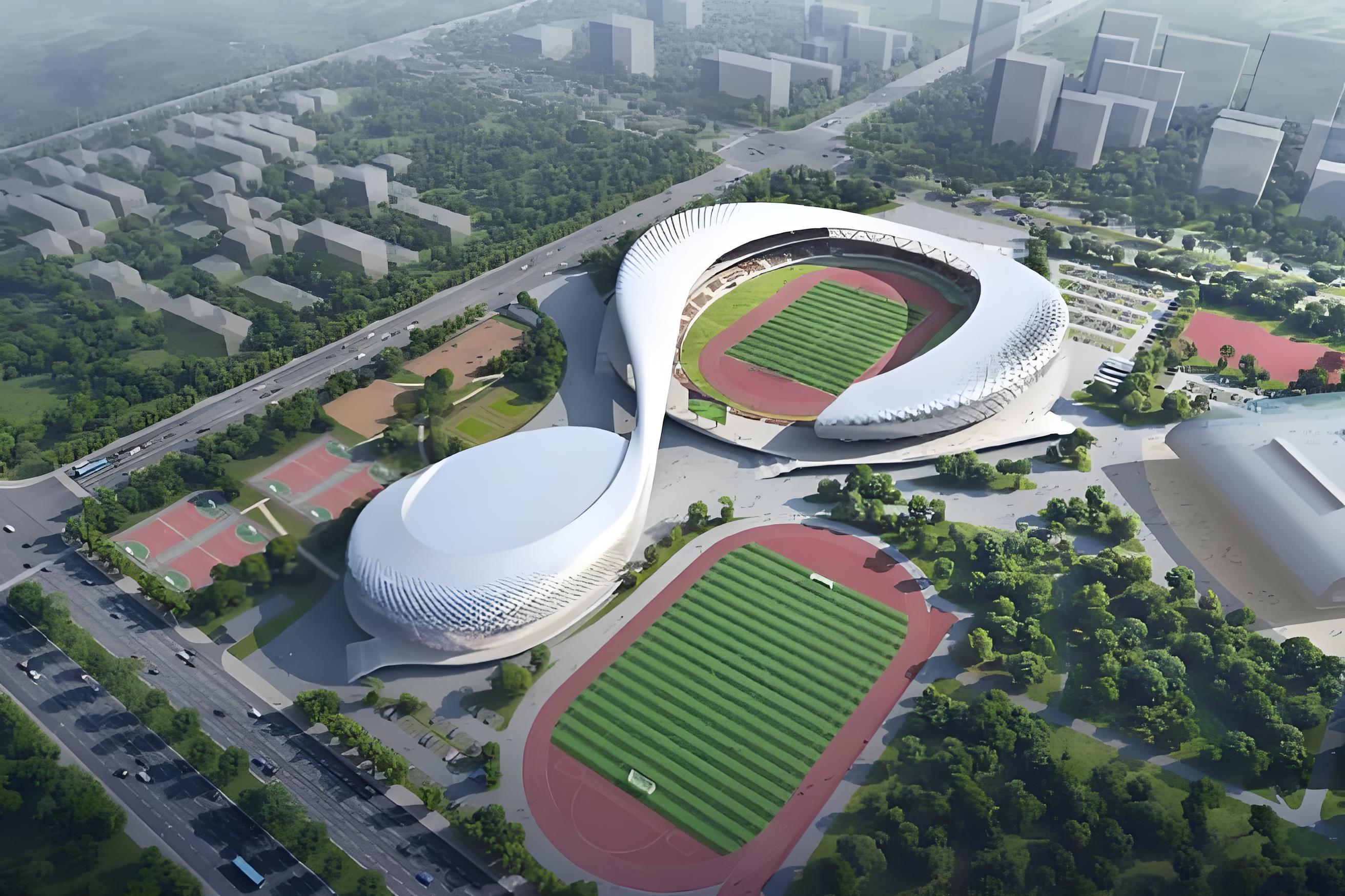

The space frame structure is a spatial grid structure composed of multiple members arranged in a certain pattern, characterized by light weight, high stiffness, and good seismic performance. Space frame structures can achieve large-span column-free spaces, making them particularly suitable for applications requiring large spaces, such as sports stadiums, exhibition centers, and airport terminals.

Space frame nodes typically use welded or bolted connections, offering convenient and quick construction. Based on their force-bearing characteristics, space frame structures can be divided into two main forms: flat space frames and curved space frames.

5. Profiled Steel Sheet Composite Floor/Wall Panels

Profiled steel sheet composite floor/wall panels are common lightweight steel structure products, consisting of profiled steel sheets and concrete. The profiled steel sheets (usually galvanized or galvalume steel sheets) are roll-formed into specific wave patterns (such as YX type, closed-type decking, open-type decking, etc.), forming a “steel skeleton” with strong unidirectional or bidirectional mechanical properties.

Ordinary concrete or lightweight aggregate concrete is poured (or prefabricated panels are laid) above the profiled steel sheets (for floors) or inside (for sandwich wall panels). The concrete and profiled steel sheets are closely bonded through shear connectors (such as studs, special wave patterns) to form a composite action that jointly bears the load.

Performance Characteristics of Steel Structure Products

Steel structure products possess a series of unique performance characteristics that determine their wide range of applications:

-

High Strength, Light Weight: The yield strength (fy) of steel is generally ≥235MPa (Q235 steel), far exceeding that of concrete (C30 concrete compressive strength is only 30MPa). Its elastic modulus (E) reaches 206GPa, 7-10 times that of concrete. This “high specific strength” (strength/density) characteristic makes the cross-sections of steel members only 1/3-1/5 of those of concrete members.

-

Good Plasticity and Toughness: Steel has good plasticity and toughness, capable of withstanding large deformation without sudden fracture under seismic loads, giving steel structures excellent seismic performance.

-

High Industrialization Level, Short Construction Period: Steel structure components can be prefabricated in factories, ensuring quality control and quick on-site installation, effectively shortening the construction period. The manufacturing and installation of steel structures are highly mechanized, representing the highest level of industrialization among all structures.

-

Good Sealing Performance: Steel structures use welded or bolted connections, offering overall good sealing performance, suitable for containers, pipelines, and other applications requiring airtightness. Welded structures can achieve complete sealing, making them ideal for high-pressure vessels, large oil tanks, and pressure pipelines.

-

Heat-Resistant but Non-Fireproof: Steel maintains stable performance at temperatures below 150°C, making steel structures suitable for hot production lines. However, at 300°C-400°C, the strength and elastic modulus of steel significantly decrease, and at 600°C, the tensile strength of steel approaches zero.

-

Poor Corrosion Resistance: Steel structures are prone to rusting in humid or corrosive environments. Therefore, general steel structures require rust-proof treatment, hot-dip galvanizing, or industrial coating application, along with regular maintenance.

Application Scenarios of Steel Structure Products

Based on the above product types and performance characteristics, steel structures have wide applications in various fields:

1. Industrial Construction Field

Industrial construction is one of the most widely applied fields for steel structures, especially in heavy-load environments where steel structures demonstrate significant advantages.

Power Plant Main Buildings and Boiler Houses: The main building must support heavy equipment such as steam turbines (weighing over 300 tons each) and generators, using a steel frame-bracing system with column spacing up to 12m×12m, providing flexibility in equipment layout. The high-temperature environment in boiler houses (furnace temperature exceeding 1200°C) requires steel members to be coated with thick fire-resistant coatings (fire resistance rating of 3.0 hours) and insulation layers to keep surface temperatures ≤150°C.

Steel Mills and Locomotive Plants: The rolling mill workshop in steel mills must bear crane loads of up to 200 tons, using box columns and welded H-shaped steel beams with stiffeners in the joint areas to enhance shear capacity. The assembly workshop in locomotive plants requires clear heights of over 30 meters, achieved with a steel space frame roof (3 meters thick) for column-free space, complemented by a suspended crane system.

2. Transportation Engineering Field

Steel structures play an irreplaceable role in transportation engineering, particularly in bridge construction.

Bridge Engineering: Simply supported beam bridges (span ≤50m) use I-shaped steel box girders, prefabricated in sections and transported to the site for bolted-welded connections, reducing construction time by 60% compared to concrete. Continuous beam bridges (span 50-150m) use variable cross-section steel box girders, constructed using the cantilever pouring method for scaffold-free construction. Among truss bridges, Bailey bridges (assembled steel trusses) use 321-type standard components (single truss bearing capacity of 45 tons), suitable for emergency bridges due to their modular assembly.

Railway Stations and Metro Projects: Large railway stations mostly use steel frame-bracing systems to achieve spacious waiting halls. In metro station open-cut construction, steel supports are the primary form of foundation pit support, offering quick installation and reusability.

3. Public Buildings Field

Public buildings have high demands for space and aesthetics, which steel structures can perfectly meet.

Sports Venues: Modern sports venues pursue large-span, column-free, visually appealing designs that can accommodate large audiences, all achievable with steel structures. The Beijing National Stadium (Bird’s Nest) steel canopy achieves a 343-meter saddle-shaped space structure using Q345B steel’s high strength, with a steel usage of only 420kg/m², reducing weight by over 60% compared to concrete structures.

Exhibition Centers and Airport Terminals: These buildings require ultra-large column-free spaces and flexible functional zoning, making space frame and space truss structures ideal choices. For example, the Shanghai National Exhibition Center uses large-span steel truss structures to achieve 28,000 square meters of column-free space per exhibition hall.

4. High-Rise and Super-Tall Buildings

High-rise and super-tall buildings are among the most classic and common applications of steel structures, where steel’s high strength and excellent seismic performance make it an ideal choice for such buildings.

Steel structures can withstand enormous loads and strong wind pressures while being relatively lightweight, reducing the pressure on building foundations and lowering foundation construction costs. Some famous high-rise buildings worldwide, such as the Empire State Building in New York and the Willis Tower in Chicago, use steel structures.

The flexibility of steel structures also allows architects to create unique appearances and structural forms, meeting both modern architectural aesthetics and functional requirements. In super-tall buildings, structural systems like “steel frame + core tube” or “mega frame + bracing” are commonly used.

5. Temporary Buildings and Emergency Engineering

Steel structures have unique advantages in temporary buildings and emergency projects, mainly reflected in quick construction and reusability.

Site Activity Houses: Using light steel frame structures, components are highly standardized, allowing for quick assembly and disassembly to meet temporary office and accommodation needs on construction sites.

Emergency Bridges: During the Wenchuan earthquake relief, over 500 temporary crossings were built using assembled steel trusses, with modular designs enabling the erection of 200-meter spans within 48 hours.

Medical Emergency Facilities: During the COVID-19 pandemic, the Huoshenshan and Leishenshan hospitals in Wuhan were rapidly constructed using steel container houses, demonstrating the advantages of steel structures in emergency medical facility construction.

Special Applications of Steel Structures in the Petroleum Industry

The petroleum industry is a crucial field for steel structure applications, where the special working environment imposes higher demands on steel structures:

1. Offshore Oil Platforms

Offshore oil platforms are the most representative application of steel structures in the petroleum industry. Based on water depth, platforms can be divided into fixed platforms and floating platforms:

Fixed Platforms: Suitable for waters less than 500 meters deep, mainly using jacket platform structures. These platforms consist of steel piles (1.5-2.5m in diameter) driven into the seabed, connected by a jacket (truss structure) above, and then deck modules are installed. A typical example is the “Ocean Oil 981” platform in the Bohai Sea, with steel usage exceeding 30,000 tons, capable of withstanding once-a-century storms.

Floating Production Storage and Offloading (FPSO) Units: Suitable for deepwater oil fields, using ship hull steel structures (yield strength ≥355MPa) combined with upper modules. For example, the “Ocean Oil 117” FPSO has a length of 323 meters, a width of 63 meters, and a storage capacity of 2 million barrels, with the hull steel structure requiring 20 years of maintenance-free service.

2. Onshore Petroleum Facilities

Refinery Process Frames: The frames for catalytic cracking, hydrocracking, and other refinery units often exceed 50 meters in height, using multi-layer steel frame structures. Frame columns are mostly round steel pipes (800-1200mm in diameter), beams are H-shaped steel, and nodes use full penetration welds. For example, the second phase of the Zhenhai Refinery project involved 80,000 tons of steel structures.

Oil Storage Tanks: Large crude oil storage tanks (100,000 cubic meters) use floating roof tank structures, with tank walls made of 12-15mm thick steel plates (SPV490Q) welded together, and ring foundations at the bottom. Steel structures require strict corrosion protection (such as sacrificial anode protection).

Pipeline Supports: Long-distance oil pipelines use steel structure supports to cross obstacles, such as the 550-meter single-span truss crossing the Yellow River in the West-East Gas Transmission Project, using 12,000 tons of steel.

3. Special Environment Adaptations

Steel structures in the petroleum industry face special challenges such as marine atmospheric corrosion and H2S stress corrosion, requiring:

Material Selection: Offshore platforms use weather-resistant steel (such as Q345NH) or duplex stainless steel (such as 2205), while high-temperature areas in refineries use chromium-molybdenum steel (such as 15CrMoR).

Corrosion Protection Measures: Including hot-dip galvanizing (thickness ≥85μm), aluminum spraying (thickness ≥150μm), and composite coating systems (such as epoxy zinc-rich primer + polyurethane topcoat).

Fire Protection: Critical areas use thick fire-resistant coatings (fire resistance rating of 2-3 hours) or fire protection cladding systems.

Development Trends and Challenges of Steel Structures

With technological advancements and increasing environmental requirements, steel structure buildings face new opportunities and challenges:

-

Green Building and Sustainable Development: Steel structure buildings are recyclable, aligning with green building concepts. Steel has a recycling rate of over 90%, far exceeding that of concrete buildings.

-

Promotion of Prefabricated Buildings: Steel structures naturally align with prefabricated buildings, and with national policies promoting prefabricated construction, steel structure applications will become more widespread.

-

Advancements in Fire and Corrosion Protection Technologies: New fire-resistant coatings and corrosion protection technologies are gradually addressing steel structures’ poor fire resistance and susceptibility to corrosion.

-

Intelligent Manufacturing and BIM Technology: Steel structure manufacturing is moving towards intelligent development, with BIM technology improving design and construction collaboration efficiency.

-

Cost and Market Acceptance: Despite numerous advantages, steel structures still have higher costs than traditional structures in some areas, and market acceptance needs further improvement.

Conclusion

Steel structure products are diverse, with wide-ranging applications, from industrial buildings to super-tall structures, from bridges to sports venues, and even petroleum industry facilities, where they play irreplaceable roles. With technological advancements and increasing environmental requirements, the application prospects of steel structure buildings will become even broader. In the future, steel structures will play a more significant role in green buildings, prefabricated construction, and other fields, contributing to the development of the construction industry.

Leave a Reply

Want to join the discussion?Feel free to contribute!