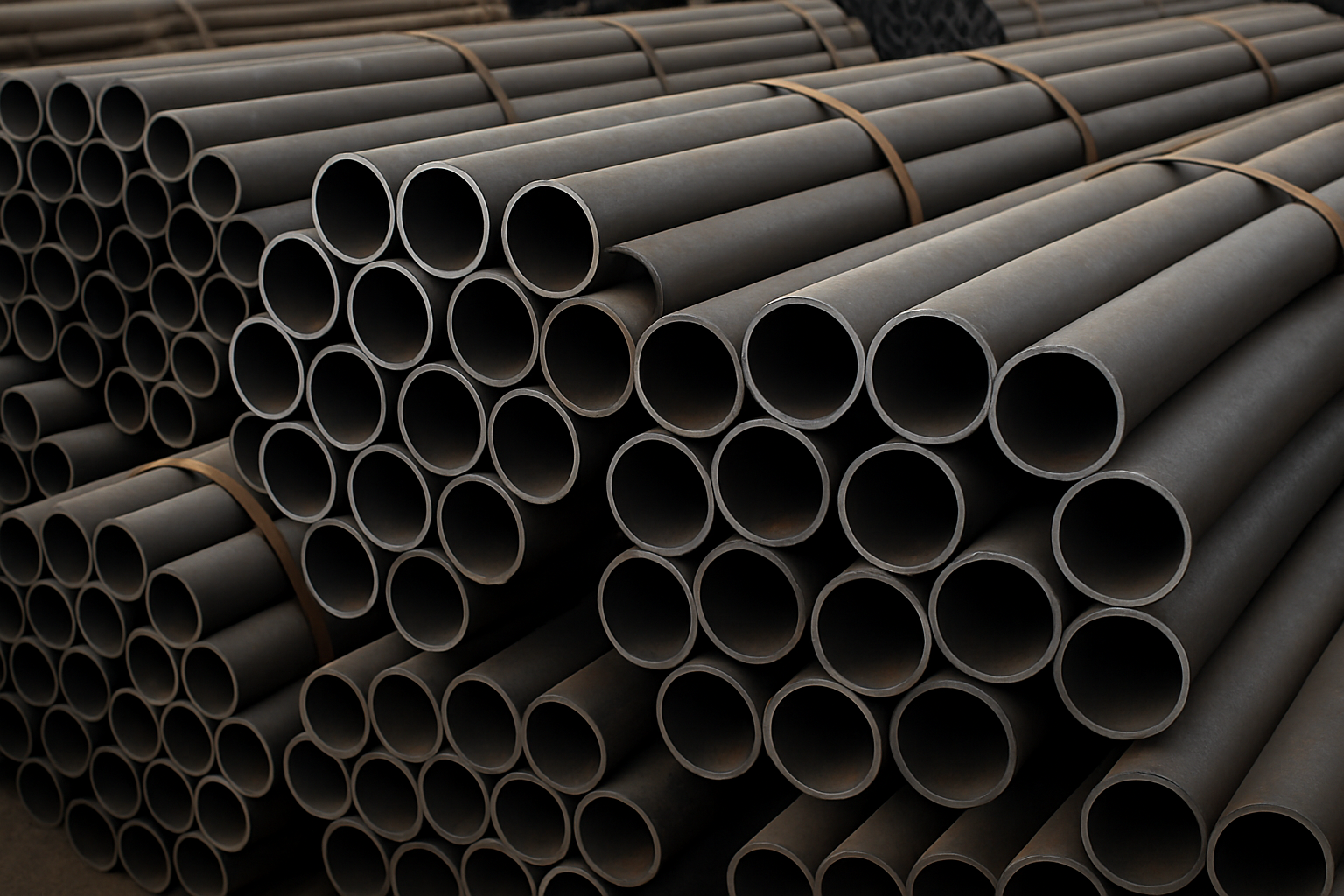

In the world of industrial manufacturing and structural engineering, carbon steel pipes are a commonplace basic material. Though they may seem unremarkable, they are ubiquitous across numerous industries, including steel structures, equipment manufacturing, furniture, agricultural facilities, scaffolding, and oil transportation.

As a manufacturer of carbon steel pipes, we want to share with you that producing a qualified carbon steel pipe is far more than just “rolling a sheet of iron.” It is a high-precision process that involves meticulous selection of raw materials, forming and welding, sizing, and finishing.

This article will take “raw materials” and “process control” as its main themes, guiding you through the production process of a carbon steel pipe and addressing the various questions you may encounter during procurement and use—why do some pipes bend or crack easily? Why are some welds unstable? Why does the service life of some exceed expectations?

- Carbon Steel Pipe Raw Materials: Similar in Appearance, Yet Worlds Apart in Quality

Common Material Analysis: What are the differences between Q195, Q215, Q235, and Q345?

The performance of carbon steel pipes primarily depends on the material of the steel strip used as raw material. The following categories are commonly used in China:

| Material | Yield Strength (MPa) | Characteristics | Application Scenarios |

| Q195 | ≥195 | Soft,good ductility,strong weldability | Furniture tubes,display racks,lightweight structural components |

| Q215 | ≥215 | Moderate strength,good formability | General structural support components |

| Q235 | ≥235 | Widest application, high strength,and versatile | Construction scaffolding,equipment frames,agricultural greenhouses |

| Q345 | ≥345 | High strength,pressure-resistant,and impact-resistant | Industrial supports,cable trays,power structures |

Recommendation:

For non-load-bearing structures (such as display racks, shelves, furniture, etc.), Q195 meets performance requirements while offering cost advantages.

For structural supports, scaffolding, and equipment frames, it is recommended to use Q235 or higher grades to ensure safety margins.

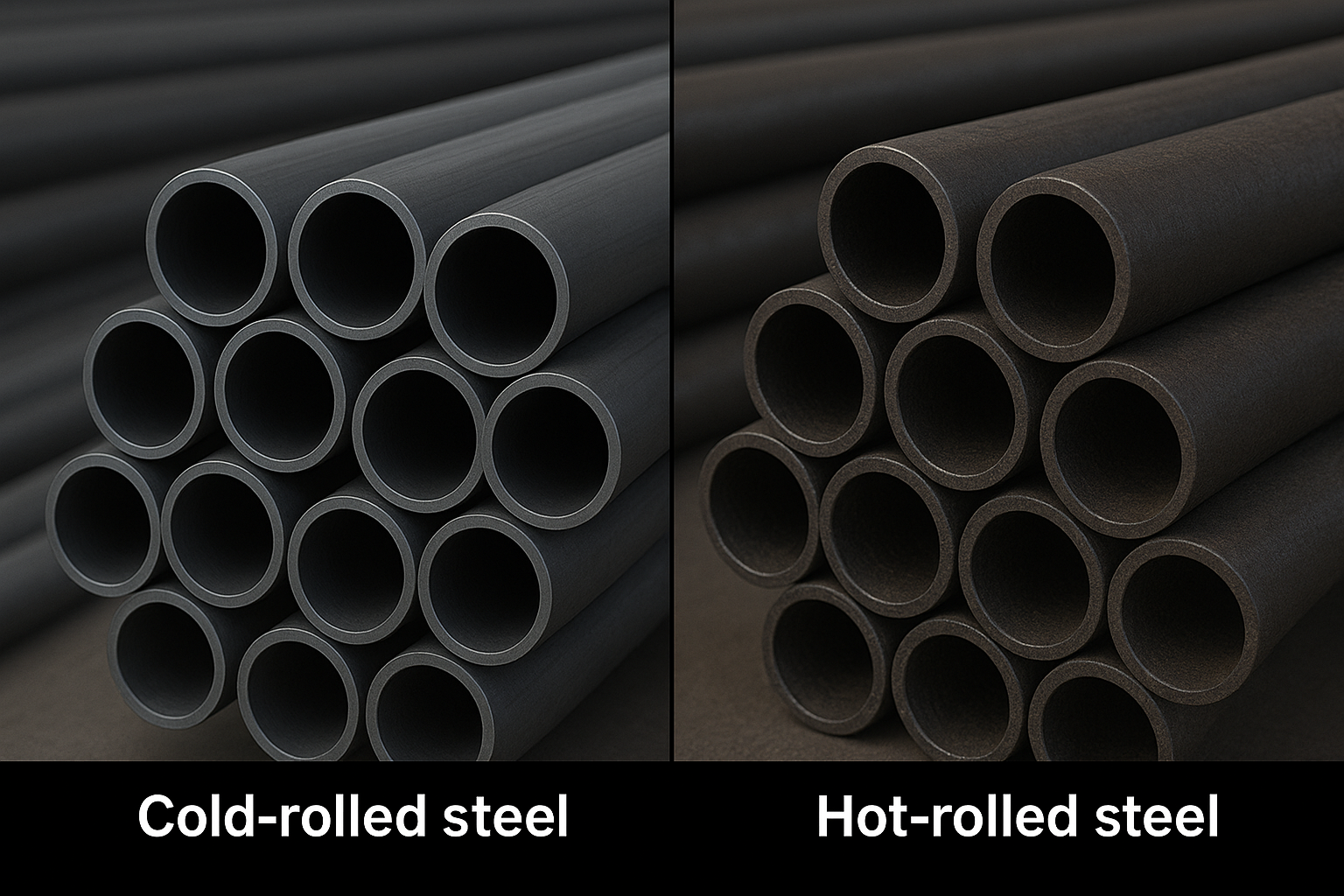

Hot-rolled steel strip vs. cold-rolled steel strip: What are the differences?

Carbon steel pipes primarily use hot-rolled or cold-rolled steel strips as raw materials, with the following differences:

| Item | Hot-rolled steel strip | Cold-rolled steel strip |

| Surface | Rough, dark color | Bright, smooth surface |

| Cost | Lower | Higher |

| Formability | Good | Prone to cracking (note for thicknesses less than 1.2mm) |

| Application | General structural tubes | Precision tubes, thin-walled tubes |

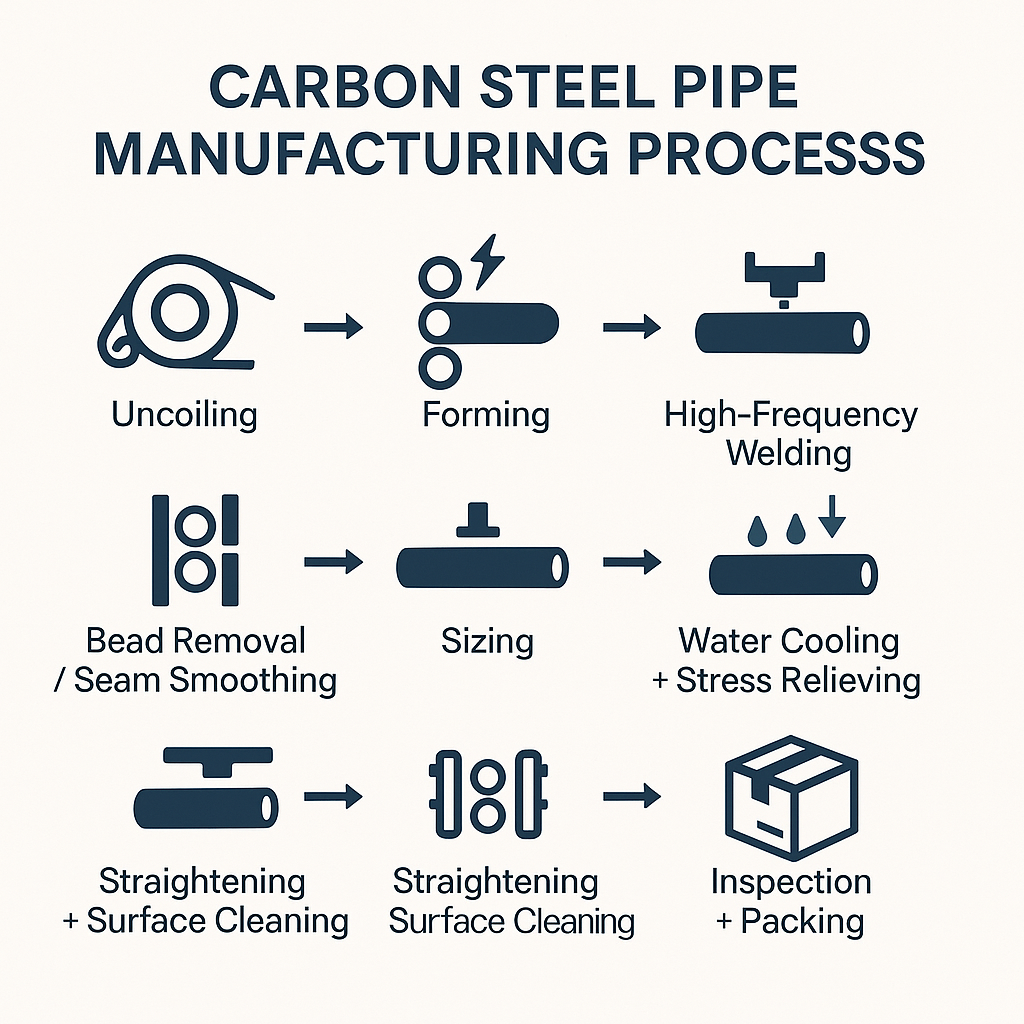

- How is a carbon steel tube made?

Many people believe that steel tubes are simply rolled into circles from steel strips. In reality, the entire production process involves at least 9 key steps, each of which affects the final product’s quality and service life.

A.Steel Strip Uncoiling

Uncoil and flatten large rolls of hot-rolled/cold-rolled steel strips.

Maintain stable steel strip tension to avoid slackening or excessive stretching due to tension fluctuations.

Control steel strip tension and thickness uniformity to lay a stable foundation for subsequent welding.

B.Forming (Roll Forming)

Using a series of forming dies, the flat steel strip is bent into a circular, square, or rectangular shape.

The bending radius must be uniform; otherwise, the tube shape will be distorted.

The more forming dies used, the rounder the tube shape and the smaller the error.

C.High-Frequency Welding (ERW) -Core process status

High-frequency current is used to heat the edges of the steel strip, causing them to melt rapidly and fuse into a weld seam.

High-frequency machine power control must be precise; if the temperature is too low, the weld will not be secure, and if it is too high, it will burn through.

Welding position offset can cause “offset seam” issues, affecting strength.

Note: A truly good weld is one where the weld seam is “invisible” — the weld seamlessly transitions into the base material with no noticeable unevenness or pores.

D.Weld Bead Removal / Weld Seam Finishing

After welding is completed, internal and external weld scars must be removed in a timely manner to ensure the aesthetics of the weld and avoid blockages.

High-quality pipes typically require the external weld surface to be smooth, free of pores, and free of undercuts.

E.Sizing and Shaping

Through mold design, process parameter control, and equipment precision, the steel pipe ultimately achieves the standard outer diameter and ensures an ovality of ≤±0.2 mm.

Inaccurate pipe diameters will affect subsequent processing such as butt welding and socket welding.

F.Length Cutting

Common single carbon steel pipes come in standard lengths of 6 meters, 9 meters, or 12 meters, but can also be custom cut to customer specifications.

For construction sites, it is recommended to choose full-length pipes to reduce the number of joints.

G.Water-Cooled Cooling + Stress Relief

During welding and shaping, the steel reaches high temperatures and requires rapid cooling to prevent deformation.

High temperature → water cooling → buffer platform to prevent cracks caused by rapid cooling.

Precision tubes also require annealing treatment to release internal stress.

H.Straightening + Surface Cleaning

Control tube bending within ±3 mm/meter and remove surface oil stains and iron filings.

If painting or galvanizing is required, surface pretreatment is particularly critical.

I.Inspection + Packaging and Shipping

Conduct sampling inspections (dimensions, wall thickness, hardness, tensile strength), and package according to requirements after passing inspection.

Generally use hexagonal strapping; for export, use plastic film + steel strapping packaging.

High-standard customers require random third-party inspection or issuance of material certificates.

- Welding Quality: The Lifeline of Carbon Steel Tubes

Whether you are manufacturing structural components, brackets, furniture, or export products, weld quality determines the reliability of the entire tube assembly.

Common issues include:

❌ Off-center welds → unstable load-bearing structures prone to cracking;

❌ Porosity → hollow welds with insufficient strength;

❌ Weld spatter → Unattractive appearance, affecting coating;

❌ Black lines, peeling → Material or welding control errors.

- What should you focus on when selecting carbon steel pipes?

As an end purchaser, you do not need to master the entire manufacturing process, but the following four points can help you purchase more efficiently and with peace of mind:

| Focus points | Why it is important | How to judge |

| Material grade | Determines strength and service life | Require original material certification or tensile test report |

| Wall thickness control | Too thin is not strong, too thick is wasteful | Use a micrometer for spot checks, or review the manufacturer’s specified wall thickness range |

| Weld quality | Critical for structural safety | Visually inspect for defects such as black lines, peeling, or porosity |

| Straightness | Affects assembly and welding precision | Place the pipe on the ground and observe for any wobbling |

Conclusion: A good pipe is meticulously crafted from raw materials to manufacturing processes

In today’s market where prices are increasingly homogeneous, what truly determines whether a carbon steel pipe is “reliable and practical” is not its cost, but the attention to detail in material selection and manufacturing processes.

Carbon steel pipes may seem simple, but they are technically sophisticated.

If you are facing a procurement decision, feel free to share your usage environment, load-bearing requirements, and processing specifications with us. We can provide professional advice from material selection to specification ratios, helping you avoid using the wrong materials, wasting resources, or missing deadlines.