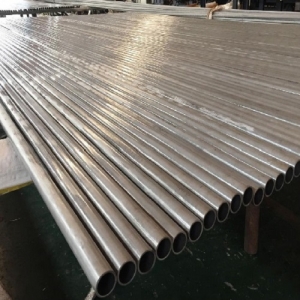

Seamless Steel Pipes

According to production’s technology and craft of steel tube, the steel pipes may separately be produced into basic two categories such as seamless pipe and welded steel pipe (Electric resistance welding pipe and Spiral welded pipe).

Usage

Seamless steel tube often could be formed and produced through hot rolled craft and cold drawn technology. Certainly the strength of hot rolled seamless steel pipes rather than cold drawn seamless steel tubes. About its common uses respectively are

- Steam pipeline,

- Gas pipeline,

- Liquefied gas pipeline,

- Natural gas pipelines,

- All kinds of pipelines for petroleum products,

- Pipelines for conveying various other gases or liquids.

Dimension

Sino East Steel may produce GB standard of steel pipe to gratify domestic buyers’ demand, amid also provide wide range of international industrial standard such as ASTM, ANSI and API, ASME and so on to satisfy oversea customers.

Nominal O.D (Outer Diameter, inch)

1/2” to 24”

Wall Thickness (inch)

40” to 4,000”

Advantage

- Actually as the advantage of higher pressure-bearing capacity of seamless steel pipes, the seamless steel pipe may involve in more broad range of uses.

- Compare between solid steel (steel rod) and seamless steel pipe, the seamless steel tubes have lighter weight when its bending and torsional strength are the same, so it is an economic section steel.

- Manufacturing the ring spare parts by seamless steel pipe can improve the utilization rate of materials, simplify the manufacturing process and save material and processing time.

Seamless Steel VS Stainless Steel

Low carbon seamless steel pipe are quit similar to seamless stainless steel pipes according its process and craft, however, stainless steel pipe may be with higher flexibility and resisted acid because of content of low carbon.

TAG

mild steel seamless pipes black seamless steel pipes seamless stainless steel tubing seamless carbon steel pipes

seamless steel pipe schedule 40 seamless steel pipe schedule 80 seamless steel pipe a106