Discover the seamless steel pipe manufacturing process, from the selection of raw materials to the production of high-quality finished products. This article provides an overview of the techniques involved, including the choice of raw materials, the manufacturing process, and the quality control measures implemented. Gain insights into the seamless steel pipe industry, its production stages, and the importance of quality control. Explore the world of seamless steel pipe manufacturing and its significance in various industries.

Introduction:

Seamless steel pipes are a crucial component in various industries, including oil and gas, construction, and automotive. Understanding the seamless steel pipe manufacturing process is essential for ensuring high-quality products that meet industry standards.

This article presents a comprehensive overview of the process, starting from the selection of raw materials to the final inspection of finished pipes. By delving into the techniques and quality control measures employed, readers can gain valuable insights into the production stages and the significance of seamless steel pipes in different sectors.

Raw Materials for Seamless Steel Pipe Production

The seamless steel pipes manufacturing process begins with the selection of suitable raw materials. The primary material used is carbon steel due to its excellent mechanical properties and cost-effectiveness. Carbon steel is available in different grades, such as ASTM A106, ASTM A53, and API 5L. These grades vary in terms of chemical composition and mechanical properties, allowing manufacturers to produce pipes suitable for specific applications.

Carbon steel, alloy steel, and stainless steel also utilize in certain cases where corrosion-resistance mechanical properties requiring. Alloying elements like chromium, molybdenum, and nickel can add to improve the properties of the steel. Additionally, the choice of raw materials depends on factors such as the operating conditions, intended application, and customer specifications.

Once the raw materials procure, they undergo a rigorous inspection process to ensure their quality and conformance to industry standards. This includes chemical analysis, mechanical testing, and visual inspections. Only materials that meet the specifications approving for further processing.

Transition: Now that we have explored the selection of raw materials, let’s delve into the seamless steel pipe manufacturing techniques.

Seamless Steel Pipe Manufacturing Techniques:

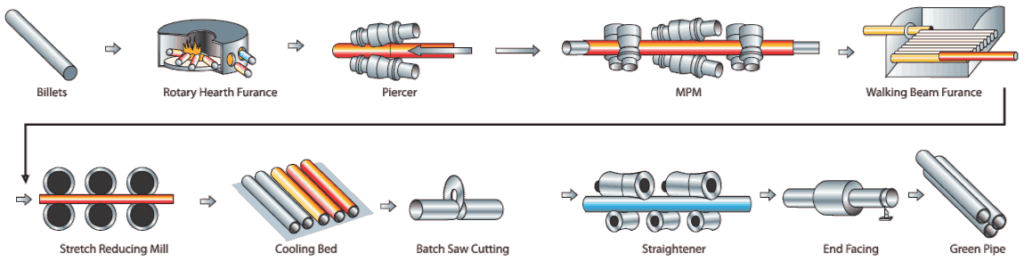

The manufacturing of seamless steel pipes involves several key techniques that ensure the production of pipes with superior strength and reliability. These techniques include piercing, elongation, and heat treatment.

- Elongation: After piercing, the hollow shell elongates to the desired length and diameter. This is typically done through a process of elongation or elongation rolling. The hollow shell passes through a series of elongation mills that reduce its diameter and increase its length. This process helps improve the mechanical properties of the pipe such as its tensile strength and toughness.

- Heat Treatment: Heat treatment is a crucial step in the manufacturing process. That enhances the properties of the seamless steel pipe. It involves subjecting the pipe to high temperatures followed by controlled cooling. The heat treatment process includes processes like annealing, normalizing, quenching, and tempering. Thus these processes help refine the microstructure of the steel, improve its mechanical properties, and remove any residual stresses.

Quality Control in Seamless Steel Pipe Production:

Ensuring the quality of seamless steel pipes is of utmost importance to meet industry standards and customer requirements. Quality control measures implement throughout the manufacturing process to detect any defects or deviations and ensure the production of high-quality pipes.

- Raw Material Inspection: As mentioned earlier, raw materials undergo rigorous inspection before they approve for production. This includes chemical composition analysis, mechanical testing, and visual inspections to ensure they meet the required specifications.

- In-process Inspection: During the manufacturing process, various inspections carry out to monitor the quality of the pipes at different stages. This includes dimensional checks, visual inspections, non-destructive testing (NDT) methods like ultrasonic and magnetic particle inspection, and mechanical testing such as tensile and hardness testing. These inspections help identify any defects or deviations and allow for corrective actions to be taken.

Conclusion

In conclusion, the seamless steel pipe manufacturing process involves careful selection of raw materials, precise manufacturing techniques, and stringent quality control measures. These measures ensure the production of high-quality seamless steel pipes that meet industry standards and customer expectations.

With their superior strength, reliability, and versatility, seamless steel pipes play a vital role in various industries, providing a seamless flow of materials and fluids. In summary, the seamless steel pipe manufacturing process encompasses the selection of raw materials, piercing, elongation, heat treatment, and rigorous quality control measures.

These pipes find extensive applications in industries such as oil and gas, construction, and automotive, where their strength, durability, and dimensional accuracy are of utmost importance. By adhering to strict manufacturing standards and implementing effective quality control, seamless steel pipe manufacturers contribute to the seamless flow of materials and fluids across various sectors.