Description

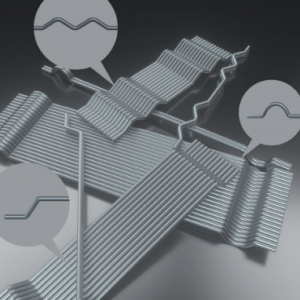

Application of end hooked glued&loose steel fiber

1. Industrial flooring: End-hooked glued and lose steel fibers are commonly used in industrial flooring to improve its resistance to abrasion and impact. This includes applications such as warehouses, factories, and other facilities with heavy machinery and equipment.

2. Precast concrete products: Steel fibers are added to precast concrete products such as retaining walls, pipes, and barriers to improve their strength and durability during transportation and handling.

3. Shotcrete: Shotcrete is a construction technique that involves spraying concrete onto a surface. By adding end hooked glued and loose steel fibers to the mixture, shotcrete becomes more resistant to cracking and improves its overall strength. This technique is commonly used in the construction of tunnels, bridges, and other infrastructure projects.

4. Tunnel linings: Steel fibers are added to the concrete used for tunnel linings to improve its resistance to the stresses and strains of the surrounding soil. This helps to prevent cracking and ensure the longevity of the structure.

5. Parking garages: End hooked glued and loose steel fibers are used in the construction of parking garages to improve the concrete’s ability to withstand the weight and impact of vehicles.

6. Bridges: Steel fibers are often added to the concrete used in bridge construction to improve its strength and durability, as well as to prevent cracking and reduce maintenance costs.

7. Residential and commercial buildings: End hooked glued and loose steel fibers can be used in the construction of residential and commercial buildings to improve the concrete’s strength and durability, as well as to enhance its resistance to cracking and weathering.

Others want to know

Q1:The role of steel fiber in soil?

1. Ordinary concrete: It has compressive properties, but it is a brittle material without post-crack toughness, and the tensile strength of plain concrete itself is not considered in structural calculations.

2. Concrete reinforcement: reinforced by steel bars or steel mesh, reinforced by prestressed steel bars, reinforced by steel fibers.

3. Steel fiber reinforced concrete: a multiphase composite building material. Compared with ordinary concrete, the main advantages are tensile strength and flexural strength。 And shear strength, impact resistance, fatigue strength, bending toughness, blast resistance, and crack resistance are all greatly improved, and the freeze-thaw resistance, heat resistance, Corrosion, and other properties are also significantly improved.

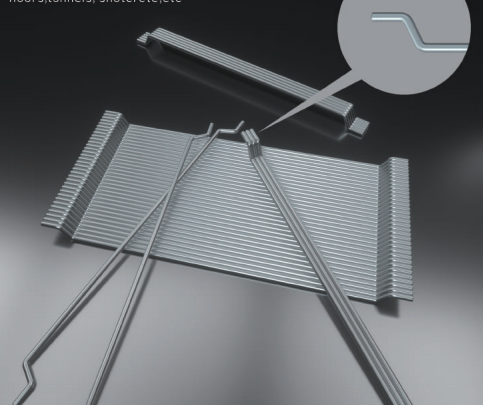

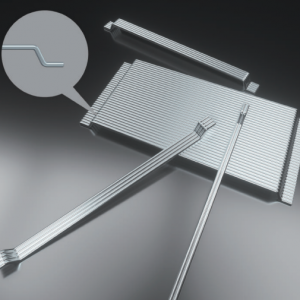

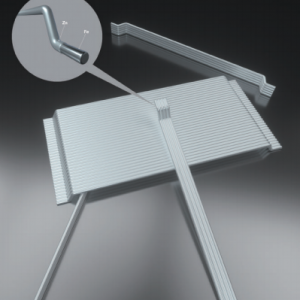

Q2:What is hooked-end steel Fibres?

Hooked-end steel fibers are a type of reinforcement used in concrete to improve its strength and durability. They are made of high-strength steel wire and have a hooked end that helps to anchor them in the concrete matrix. The hooks on the ends of the fibers prevent them from pulling out of the concrete, which increases their effectiveness in improving the concrete’s toughness and ductility.

Application Scenario

Parking Lots

Industrial Floor

Airport Runway

Ports

Brand strength

We mainly produce Hooked End Steel Fibers and Micro Steel Fibers, with an annual production capacity of 55,000 tons. It is the largest steel fiber manufacturer in China. The factory has obtained ISO9001/14001/45001 certification, and the products have also obtained the EU CE level 1 certification and South Korea KS certification. Establish a joint laboratory with the Hebei University of Technology to conduct concrete-related experiments. Over the years, Hengfeng has been making great efforts to improve the overall business and build a good image. First, measures have been made to achieve zero pollutant emissions. Second, an R&D center has been established to develop and research new products together with well-known colleges and specialists. As a result, our technology has witnessed big progress, and the products and equipment are taking lead in the world.