In various application fields such as industrial manufacturing, building structures, appliance casings, and transportation facilities, corrosion protection treatment of steel surfaces remains a critical factor in material selection. As two primary types of corrosion-resistant steel materials, galvanized steel coils and stainless steel coils are analyzed below from several aspects including material structure, corrosion resistance, processing and forming, and aesthetic appeal.

1.Material Structure and Corrosion Protection Principles: Fundamental Differences Determine Performance Outcomes

1.Material Structure and Corrosion Protection Principles: Fundamental Differences Determine Performance Outcomes

Galvanized Steel Coils: Corrosion Protection Achieved Through the “Sacrificial Anode” Principle

Galvanized steel coils are produced by applying a layer of zinc (typically through hot-dip galvanization) to the surface of ordinary carbon steel. The zinc layer isolates air and moisture, preventing oxidation and corrosion of the base material. Even if the zinc layer is damaged, it can still be corroded electrochemically to protect the underlying steel from damage. After production, galvanized steel coils can undergo additional passivation and oil coating processes to enhance their corrosion resistance and extend their service life.

Stainless steel coils: inherently corrosion-resistant

Stainless steel coils form a dense chromium-rich oxide layer on their surface through their alloy composition, fundamentally preventing oxidation reactions and exhibiting high corrosion resistance. They are particularly suitable for high-humidity environments, acidic or alkaline gas environments, marine climates, medical applications, food-grade applications, and other scenarios.

| Material | Galvanized steel coils | Stainless steel coils |

| Structure | Carbon steel substrate and zinc layer | Chromium, nickel, and other alloy steels |

| Protection mechanism | Zinc layer sacrificial anode protection | Self-passivating oxide film |

Comparison conclusion:

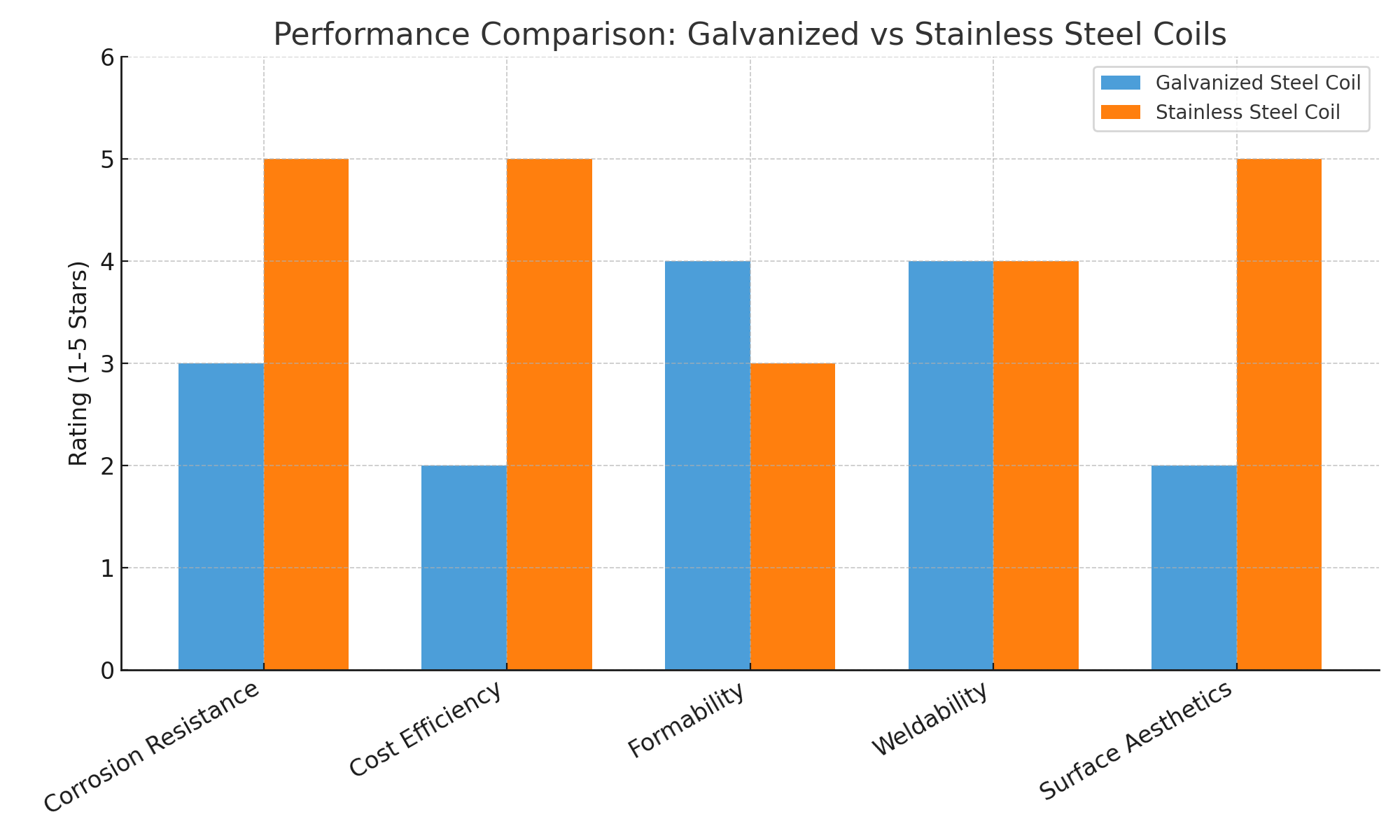

Stainless steel has a more advanced and stable corrosion protection principle, particularly excelling in high salt fog and chemical corrosion environments; galvanized steel, though less durable than stainless steel, meets most usage requirements in general scenarios and offers better cost-effectiveness.

2.Price and cost: Cost differences create market segmentation

Price has always been a core concern for customers. The price ranges of the two materials show significant differences.

The high cost of stainless steel primarily stems from its high content of chromium and nickel elements and complex smelting processes. Galvanized steel coils, on the other hand, involve applying a thin zinc layer to ordinary carbon steel, resulting in lower costs and ample production capacity.

Comparison Conclusion:

In projects with limited budgets and no special requirements for extreme environments, galvanized steel coils can significantly reduce unit costs and are the preferred material for most structural components, brackets, and non-critical corrosion-resistant parts.

3.Corrosion Resistance: Material Selection for Different Scenarios

| Application Area | Recommended Material | Reasoning |

| Photovoltaic Support Systems | Galvanized Steel Coils | Low cost, good processability, meets corrosion resistance requirements for brackets |

| Cold chain equipment housing | Stainless steel coils | High corrosion resistance, aesthetic appeal, and resistance to rust |

| Outdoor pipes/railings | Galvanized steel coils | Cost-effective and reliable corrosion protection |

| Food-grade equipment housing | Stainless steel coils | High hygiene requirements, smooth surface for easy cleaning |

| Port/marine facilities | Stainless steel coils | Highly corrosive salt fog environment requiring high corrosion resistance |

| Building Roofing Sheets | Galvanized Steel Coil | Easy to form, strong rust prevention, economical and practical |

| Appliance Back Panels | Galvanized Steel Coil | Suitable for coating and electrophoresis treatment, facilitating cost control |

4.Forming Processability & Welding Compatibility

Forming Processability:

Galvanized Steel Coil: Softer, easy to cut, bend, and stamp, suitable for complex structural components.

Stainless steel coils: High strength, requires high-performance equipment for processing, suitable for simple structures and regular shapes.

Welding compatibility:

Galvanized steel coils: Good weld-ability, but requires treatment of the zinc layer’s impact on the weld zone to avoid zinc vapor causing porosity.

Stainless steel coils: Excellent weld-ability, particularly in thin-sheet welding, but demands high standards for process and material purity.

Comparison conclusion:

For customers requiring frequent secondary forming, punching, and processing, galvanized steel coils are more suitable for production efficiency; stainless steel is suitable for structural or decorative applications, but has higher processing costs.

5.Aesthetics and surface options: Options determine visual effects

| Property | Galvanized steel coil | Stainless steel coil |

| Surface color | Silver-white, slightly rough | Silver-white/mirror finish/brushed, strong texture |

| Coating Options | Can be painted, coated, or color-coated (PPGI) | Can be brushed, mirror-finished, or electroplated |

| Aesthetic Suitability | Mid-to-low-end equipment housings, hidden structures | High-end kitchen appliances, medical equipment, architectural decoration |

Stainless steel offers stronger metallic texture and surface finish, making it suitable for visible applications; galvanized steel coils are suitable for functional applications and can be upgraded to color-coated sheets to enhance aesthetics.

Comparison conclusion:

In high-end product enclosures and architectural decoration fields where visual appeal and texture are critical, stainless steel is recommended; galvanized steel coils offer superior cost-effectiveness for low-visibility structures and internal components.

Summary recommendation: Material selection logic should prioritize “compatibility”