Against the backdrop of accelerating global energy structure transformation, solar power generation has emerged as a key driver of green and low-carbon development. As the “scaffolding” that supports photovoltaic modules and ensures the safe and stable operation of the system, the choice of material for supports directly impacts the project’s service life, installation efficiency, and long-term economic viability. Galvanized steel pipes, with their outstanding corrosion resistance, strength, processing flexibility, and cost-effectiveness, have become an indispensable key component in solar support systems.

1.Structural Challenges in Solar Systems

In photovoltaic systems, support structures are critical infrastructure used to secure and support solar panels. Whether in large-scale centralized ground-mounted power plants or distributed commercial, industrial, and residential rooftop projects, support systems must meet the following key requirements:

Long-term exposure to outdoor environments requires excellent corrosion resistance.

Ability to withstand structural loads such as wind pressure and snow loads.

Good dimensional accuracy and installation compatibility.

Support for bulk customization, rapid assembly, and low maintenance costs.

Traditional structural materials like wood, plastic, or non-corrosion-resistant steel have significant limitations when exposed to long-term, high-stress environments. Galvanized steel pipes, however, have emerged as the industry standard due to their superior structural performance and weather resistance.

2.Performance Advantages of Galvanized Steel Pipes

A.Excellent Corrosion Resistance

The surface of galvanized steel pipes is coated with a uniform, dense layer of zinc, forming a physical barrier. Additionally, zinc acts as a “sacrificial anode,” protecting the internal steel from corrosion even if the surface is scratched. They maintain stable weather resistance in coastal, high-humidity, high-salt, and high-acid/alkali environments. The corrosion resistance lifespan of hot-dip galvanized steel pipes can reach 20–30 years, outperforming conventional sprayed or cold-galvanized materials.

B.High Strength and Structural Stability

Steel inherently possesses extremely high tensile and compressive strengths, capable of meeting the wind and snow load requirements of large-scale photovoltaic arrays. The galvanized coating does not significantly affect its original structural strength, making it suitable for high-stress scenarios such as ground-mounted centralized systems, mountainous areas, and high-altitude regions.

C.Flexible Processing and Installation

Galvanized steel pipes can undergo various processing techniques such as cutting, punching, welding, and bending, and they have a high degree of standardization, making them suitable for modular assembly and industrialized rapid deployment, significantly improving construction efficiency.

D.Cost control and economic efficiency

Compared to materials such as aluminum alloy and stainless steel, galvanized steel pipes maintain structural strength and durability while offering lower raw material procurement and post-installation maintenance costs, providing a significant cost-effectiveness advantage.

3.Typical application scenarios

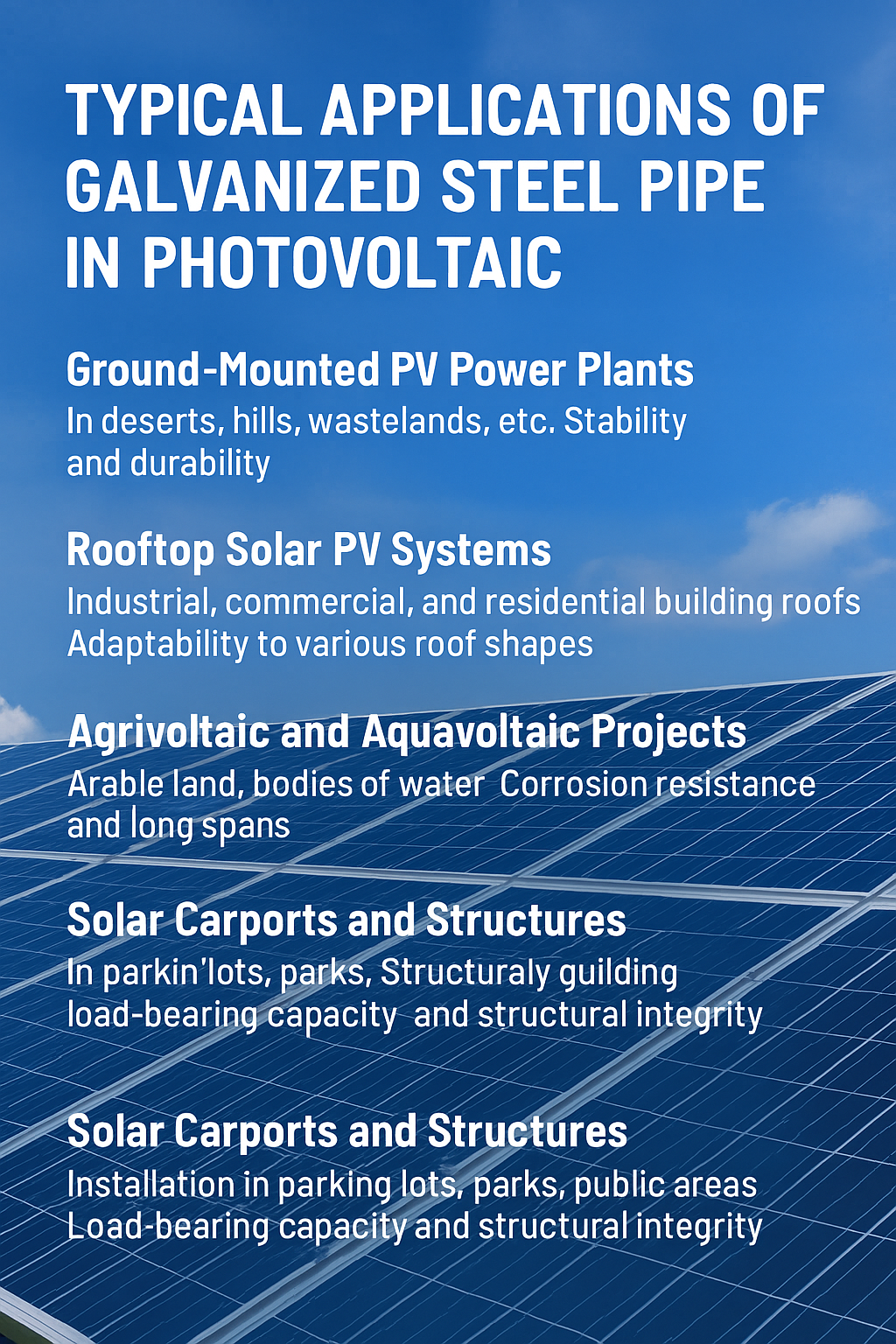

A.Ground-mounted centralized photovoltaic power plants

This is one of the most widely applied scenarios for galvanized steel pipes,suitable for large-scale open areas such as deserts,the gobi desert, hills, and tidal flats. Photovoltaic modules are typically installed on the ground using fixed or tracking mounts, which require high strength, stability, and weather resistance.

Application Features:

Hot-dip galvanized steel pipes can effectively resist high UV radiation, strong winds, and sandstorms.

They can support large-scale horizontal layouts or single/dual-axis tracking structures.

They have a service life of over 20 years with low maintenance costs.

B.Rooftop Distributed Photovoltaic Systems

Suitable for installing photovoltaic modules on the rooftops of industrial plants, commercial buildings, schools, hospitals, and residential buildings. Rooftop structures vary widely, requiring mounting systems to be lightweight, flexible, and customizable.

Application Features:

Galvanized steel pipe structures have moderate weight and strong load-bearing capacity.

Supports various structural forms such as column-mounted, sloped, and east-west orientation.

Allows flexible adjustment of installation angles and layout density based on roof space.

C.Agro-Photovoltaic and Aquaculture-Photovoltaic Projects

These projects are widely deployed over agricultural land and water bodies, enabling parallel development of agriculture/aquaculture and photovoltaic power generation to enhance land utilization efficiency.

Application Features:

Projects are often exposed to high humidity and corrosion environments, requiring extremely high corrosion resistance from the support structures.

Galvanized steel pipes can support large spans and accommodate high-column installation designs.

They are easy to adjust post-installation, facilitating agricultural machinery access or aquaculture management.

D.Photovoltaic Carports and Public Facility Photovoltaic Structures

Photovoltaic carports combine shading, parking, and power generation functions, and are widely used in public areas such as airports, industrial parks, shopping malls, and schools.

Application Features:

Galvanized steel pipes have a clean appearance and blend well with the surrounding architectural environment;

They can withstand roof loads and wind loads, ensuring long-term structural safety.

They support dual-sided module installation, enhancing power generation efficiency.

4.Full Life Cycle Economic Analysis

From an investment decision perspective, although the cost of photovoltaic system supports accounts for a small proportion of the total cost, their quality and performance are critical to the stable operation of the entire project.

| Material Comparison | Initial Procurement Cost | Maintenance Cycle | Maintenance Cost | Lifespan | Notes |

| Galvanized Steel Tubing | Low | Over 10 years | Extremely low | 20–30 years | High cost-effectiveness over the full life cycle |

| Aluminum alloy | Higher | Over 15 years | Low | Around 20 years | Lightweight but slightly inferior in impact resistance |

| Stainless steel | High | Over 20 years | Low | Around 25 years | High cost, longer project payback period |

Galvanized steel pipes achieve an ideal balance between cost-effectiveness, durability, and adaptability, making them the preferred structural material for medium to large-scale photovoltaic projects.

The solid foundation behind green energy

Though unassuming, galvanized steel pipes play a foundational and critical role in supporting solar systems for a green future. With its multi-dimensional advantages of “structural safety and cost control and environmental adaptability,” it has earned the trust of an increasing number of photovoltaic project users. Galvanized steel pipes stand at the starting point of energy structure reform, using their steel frames to support the future of clean energy.