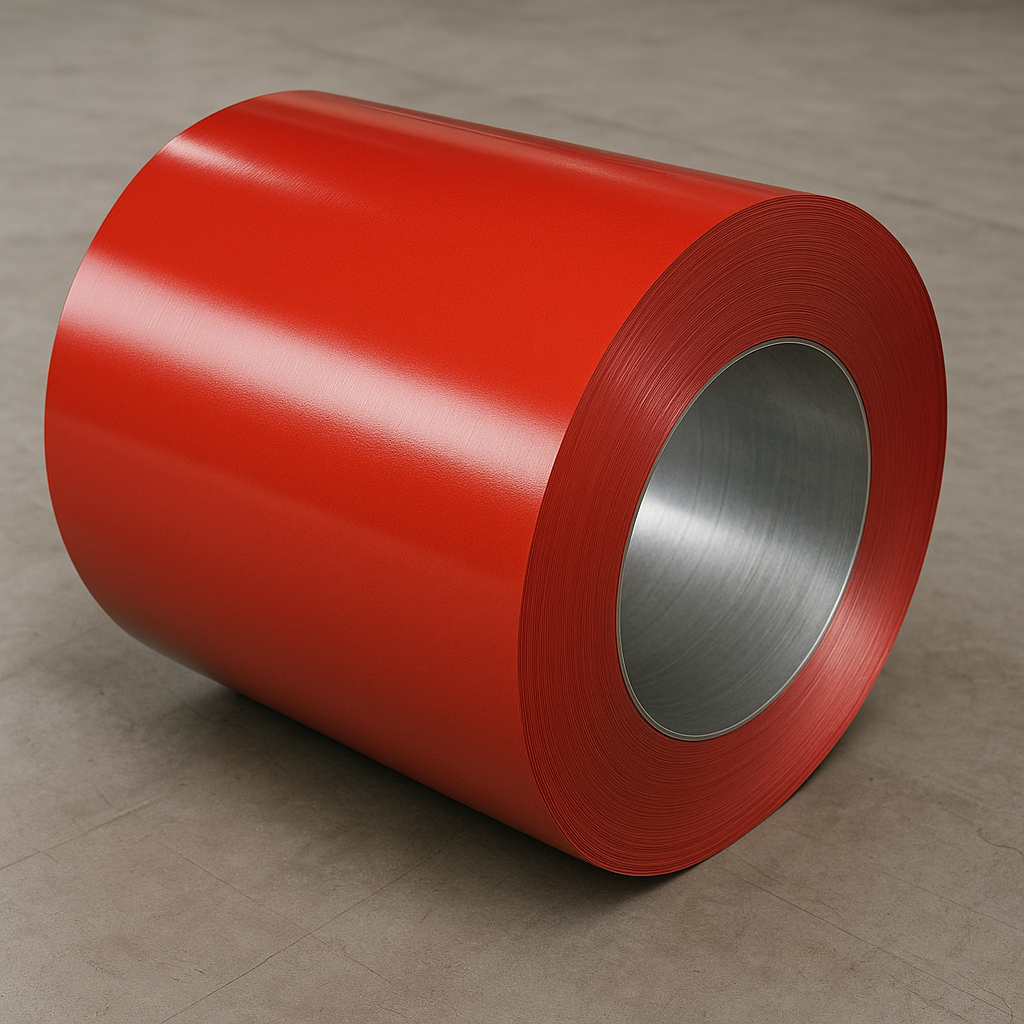

In modern construction, home appliance manufacturing, transportation, and light industry, there is an increasing demand for materials that combine functionality with aesthetic appeal. Color-coated steel coils (PPGI) are products developed in response to this trend. As an extension and evolution of galvanized steel coils, color-coated steel coils not only retain the strength and corrosion resistance of the base steel but also achieve a wide range of colors, textures, and special functions through coating processes, making them high-value-added materials that combine “structure and decoration” in one.

1.What is Color-Coated Steel Coil (PPGI)?

Color-coated steel coil (PPGI) refers to galvanized steel coil coated with one or more layers of pre-treated coatings (such as primer, topcoat, protective layer, etc.) to enhance its corrosion resistance, weather resistance, and decorative properties. PPGI combines the corrosion resistance of galvanized steel coils with the aesthetic appeal and color diversity of coatings, making it one of the most widely used steel materials across industries such as construction, home appliances, and automobiles.

Unlike ordinary galvanized steel coils (GIC), the surface of color-coated steel coils not only possesses the corrosion-resistant properties of galvanized steel coils but also offers additional color options and decorative effects through the applied paint layers, meeting the growing demands for aesthetics, design, and market requirements.

2.Evolution and Extension of Color-Coated Steel Coils

A.Multi-Layer Coating Structure Design for Enhanced Corrosion Resistance

The base is galvanized steel coil, and color-coated steel coil undergoes multiple coating processes on its surface to form the following structure:

Substrate (steel) + zinc layer + chemical pretreatment layer + primer layer + topcoat layer + protective layer (optional)

Substrate (steel body): Bears all physical properties (strength, rigidity, ductility), determining the overall coil’s formability and load-bearing capacity

Zinc layer: Provides basic corrosion protection and acts as a “sacrificial anode,” prioritizing corrosion when damaged to protect the steel substrate from erosion

Chemical pretreatment layer: Enhances adhesion between the coating and metal, serves as a secondary corrosion barrier, improves coating stability, and prevents peeling, blistering, and other quality issues in later stages

Primer layer: Provides a smooth base color and good adhesion foundation for the topcoat, enhances the overall system’s corrosion resistance and moisture resistance, absorbs part of the internal stress, and improves impact resistance and flexibility.

Topcoat layer: Determines the color, gloss, and final visual appearance of the coated coil, provides the first functional protective layer, and possesses weather resistance, corrosion resistance, and pollution resistance properties, resisting environmental factors such as UV radiation, wind and rain, and acid rain corrosion.

Protective layer (optional): Enhances scratch resistance, fingerprint resistance, or provides self-cleaning functionality, preventing scratches or stains during coil transportation and construction. Special coatings can also reflect heat or have antibacterial properties.

This composite structure significantly enhances corrosion resistance. Compared to single-layer zinc protection, multi-layer coatings offer more durable oxidation resistance, moisture resistance, and weather resistance, making them suitable for more complex outdoor environments.

B.Enrichment of colors and patterns, higher decorative value

Diversification of color expression: Galvanized steel coils have a metallic luster but are primarily silver-white or gray-white in color, offering limited decorative appeal. Color-coated steel coils achieve a rich color palette by applying coatings over the zinc layer, enhancing aesthetic appeal and visual distinction.

Refined pattern design: Complex patterns cannot be achieved on traditional galvanized steel coils, but color-coated steel coils utilize printing and lamination technologies to significantly enhance pattern expression capabilities, transforming cold steel into warm, stylish decorative materials that meet diverse customer aesthetic preferences and cultural demands.

| Application Areas | Decorative Value | Demonstration Examples |

| Building exteriors/roofs | Aesthetically pleasing, durable, uniform color, enhanced image | Industrial parks, commercial centers, residential community roofs |

| Appliance housings | Home integration, enhanced texture and user experience | Refrigerator, washing machine, water heater panels |

| Interior decoration | Replaces wall panels and wood panels, more wear-resistant and fire-resistant | Wall panels, ceilings, background walls |

| Containers and vehicle bodies | High color recognition, resistant to wind, rain, and corrosion | Marine containers, cold chain logistics vehicle bodies |

| Public facilities | Balancing aesthetics and functionality, supporting reflective/warning colors | Bus shelters, fences, signage, billboards |

C.Extended coating functions, broader functional expandability

Modern color-coated steel coil coatings not only possess traditional corrosion-resistant functions but also offer multiple functional characteristics:

Scratch-resistant, fingerprint-resistant: Suitable for appliance housings and public facilities.

Self-cleaning coating: Achieves automatic removal of surface dirt after rainwater rinsing through special coatings.

High-temperature resistance, chemical corrosion resistance: Meets the application requirements of industrial equipment and special environments.

Flame-retardant coating: Enhances safety performance and is widely used in interior decoration.

These functions significantly expand the application areas of color-coated steel coils.

D.Structural optimization for better processing adaptability

During the manufacturing process of color-coated steel coils, compared to traditional galvanized steel coils, systematic optimization has been conducted on the selection of base materials and coating formulations, effectively enhancing the flexibility and adhesion of the coating. Thanks to these improvements, color-coated steel coils can significantly reduce issues such as “paint cracking” or “peeling” during conventional and complex processing operations like shearing, bending, stamping, and roll forming, ensuring the product’s aesthetic appeal and durability.

Compared to traditional galvanized steel coils, color-coated steel coils (PPGI) are regarded as an “evolved” material that combines performance and aesthetics: they offer superior corrosion resistance, diverse coating options, and excellent forming performance, making them an ideal choice for modern architecture, cold chain equipment, appliance panels, and interior decoration applications. With the global trend toward green building development and the strong demand for infrastructure and industrial products along the “Belt and Road” initiative, color-coated steel coils are entering a period of rapid growth. Leveraging their lightweight, eco-friendly, easy-to-install, and low-maintenance cost advantages, color-coated steel coils demonstrate greater adaptability and market competitiveness in emerging markets and energy-efficient projects.