In various engineering projects such as construction engineering, municipal pipelines, agricultural irrigation, industrial plants, and HVAC systems, galvanized steel pipes are widely used in water supply, gas transmission, scaffolding, and protective applications due to their excellent corrosion resistance and reasonable price. However, as an industrial material, the service life and maintenance costs of galvanized steel pipes remain two critical metrics worthy of attention.

1.Service Life: Galvanized Steel Pipes Are More Durable

A.Superior Corrosion Resistance

Exposed carbon steel pipes are prone to oxidation and corrosion in humid or acidic/alkaline environments, with an average service life of 3–8 years, or even shorter. The galvanized coating acts as an isolating barrier, significantly delaying direct contact between the steel and oxygen, moisture, and chemical media, thereby enhancing corrosion resistance.

Hot-dip galvanized steel pipes: Service life can reach 30–50 years in normal atmospheric conditions.

Electro galvanized steel pipes: Suitable for indoor or weakly corrosive environments, with a service life of approximately 10–20 years.

For projects with long-term usage requirements (such as urban pipelines, outdoor structures, and water supply projects), galvanized steel pipes are undoubtedly a more cost-effective choice in terms of life cycle benefits.

Actual service life reference (by environment):

| Usage environment | Hot-dip galvanized steel pipe service life | Electro galvanized steel pipe service life |

| Industrial plants (outdoor) | 20–40 years | 1–5 years |

| Building indoor HVAC systems | 15–30 years | 5–10 years |

| Agricultural greenhouse structures | 10–20 years | 2–6 years |

| Municipal drainage support | Over 30 years | Not recommended for use |

B.Alloy Layer Structure Provides Deep Protection

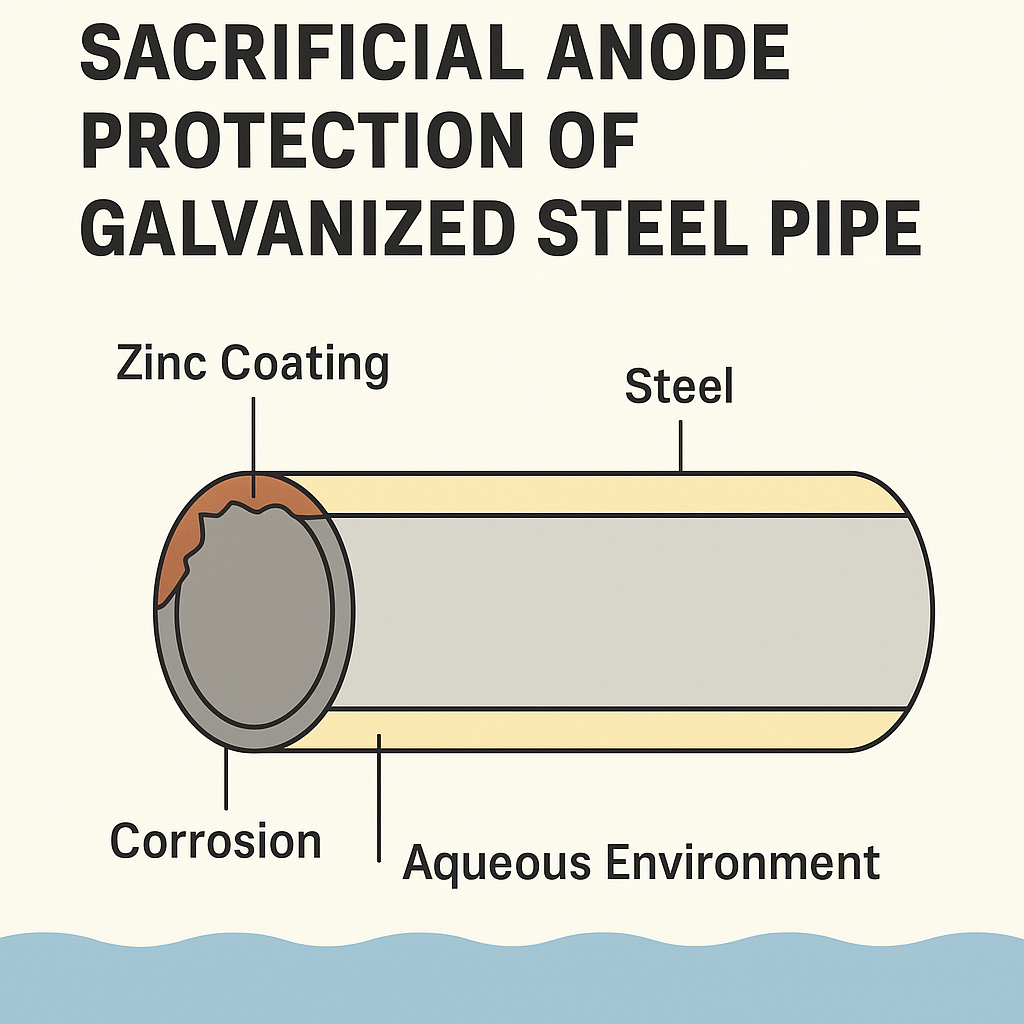

Especially for hot-dip galvanized steel pipes, the zinc layer is not merely surface-applied but forms an alloy bond with the base metal, offering superior resistance to impact and scratches. Even if small areas of the zinc layer peel off during construction or transportation, the surrounding zinc layer provides “sacrificial anode” protection, preventing localized corrosion from spreading.

C.Adaptable to various extreme environments, demonstrating stable performance

From high-humidity coastal regions, industrial pollution zones, to cold mountainous areas or saline-alkali soil regions, galvanized steel pipes exhibit excellent weather resistance, ensuring the stability of service life.

High-humidity coastal regions: High salt concentration and strong corrosion, but the galvanized layer effectively blocks salt fog penetration;

Industrial pollution zones: High concentrations of sulfur dioxide and nitrogen oxides, but the zinc layer resists chemical corrosion from acidic gases;

Cold mountainous regions: Large temperature fluctuations and frequent freezing, but hot-dip galvanized steel pipes have excellent impact resistance and crack resistance;

Salt-alkali regions: Soil with high conductivity and alkaline pH, but galvanized steel pipes still exhibit excellent resistance to soil corrosion.

In these environments, galvanized steel pipes exhibit minimal dimensional changes, stable mechanical properties, and prolonged corrosion resistance, ensuring their safety and reliability during long-term operation.

2.Maintenance costs, the hidden advantage of galvanized steel pipes

The core factors influencing maintenance costs include: corrosion and rust prevention expenses, regular inspection and repair costs, replacement frequency and labor costs, additional investments in coatings, coverings, and protective facilities, and systemic losses caused by system failure.

Maintenance advantages of galvanized steel pipes

A.Zinc layer protection, proactive corrosion prevention

Galvanized steel pipes form a dense zinc layer on the pipe surface through hot-dip galvanizing technology. This zinc layer not only blocks direct contact between moisture and air and the steel, but also actively protects the steel body through the “sacrificial anode” mechanism. When the zinc layer is damaged, surrounding zinc atoms can still delay steel corrosion through electrochemical processes.

B.Cost-effective corrosion protection solution

Compared to stainless steel, galvanized steel pipes are more cost-effective yet still offer a long corrosion resistance lifespan. Unlike black iron pipes, which require additional measures such as painting or corrosion-resistant coatings, galvanized pipes come with an inherent corrosion-resistant layer upon manufacture, enabling direct application in most environments and significantly reducing additional construction and maintenance costs.

C.Suitable for Complex Environments

Whether in high-humidity, high-salt coastal regions, industrial atmospheric pollution zones, or high-altitude freeze-thaw areas, galvanized steel pipes demonstrate stable weather resistance. Their zinc coating can withstand various chemical corrosive gases and water quality impacts, with maintenance cycles typically extended to once every 2-5 years for a simple inspection, eliminating the need for frequent interventions.

3.Lifecycle of galvanized steel pipes

Customers choosing galvanized steel pipes can enjoy the following benefits in most conventional environments:

Long maintenance-free period: No major intervention required for over 5 years

Simple maintenance tools: No specialized coating or corrosion-resistant equipment required

Low maintenance costs: Generally restored to use by replacement or reapplication of the zinc coating

Low replacement frequency: Average service life can reach 15-25 years

No impact on service life: Does not fail immediately due to minor surface rust

4.Long-term value investment

The “low maintenance and low frequency” characteristics of galvanized steel pipes can save hidden costs such as labor, materials, and downtime losses. Its “high adaptability and reliability” ensure structural stability and surface corrosion resistance even in harsh environments.

From a short-term budget perspective, galvanized steel pipes have slightly higher costs than black iron pipes. However, their significantly reduced maintenance requirements and longer service life demonstrate a clear investment return advantage over the project’s total life cycle. From a long-term perspective, galvanized steel pipes offer superior cost-effectiveness.

For customers prioritizing life cycle costs, galvanized steel pipes are not merely a material choice but also a cost control strategy and risk mitigation measure.