Description

| Standard: | API, ASTM, BS, DIN, GB, JIS |

| Certification: | API |

| Surface Treatment: | Brown painting |

| Special Pipe: | API Pipe |

| Alloy Or Not: | Non-alloy |

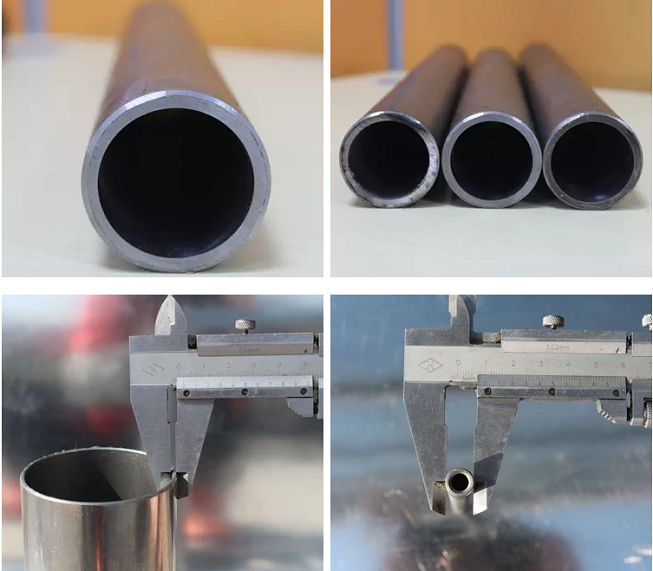

| OD: | 1/2″-10″ |

| Secondary Or Not: | Non-secondary |

| Application: | Hydraulic Pipe |

| fixed length: | 6 meter,5.8meter |

| Technique: | Cold Drawn |

| Packaging Details: | in bundle,plastic |

| Brand name: | Sino East |

| Delivery Time: | 20-30days |

The production method of the seamless steel pipe is roughly classified into a cross-rolling method and an extrusion method. The former method is to first pierce the tube with a diagonal roll and then extend it with a rolling mill. This method has a high production speed, but has high requirements on the processability of the tube blank, and is mainly suitable for the production of carbon steel and low alloy steel tubes. The latter rule is to perforate the tube blank or steel ingot with a punching machine and then extrude it into a steel tube by an extruder. This method is less efficient than the cross-rolling method and is suitable for producing high-strength alloy steel tubes. Both the cross-rolling method and the extrusion method must first heat the tube blank or the ingot, and the produced steel tube is called a hot rolled tube. Steel pipes produced by hot working can sometimes be cold worked as needed.