Among various steel products, galvanized steel pipes are widely used in fields such as construction, water supply and drainage, power, communications, agricultural facilities, and industrial manufacturing due to their outstanding comprehensive performance. The reason they are favored by engineering users and procurement parties lies in their stable and comprehensive key performance characteristics.

Galvanized steel pipes are carbon steel pipes with a zinc-coated surface. Essentially, they are ordinary steel pipes processed through a “galvanizing process” to form a dense zinc layer on their surface, thereby enhancing the pipe’s corrosion resistance and service life.

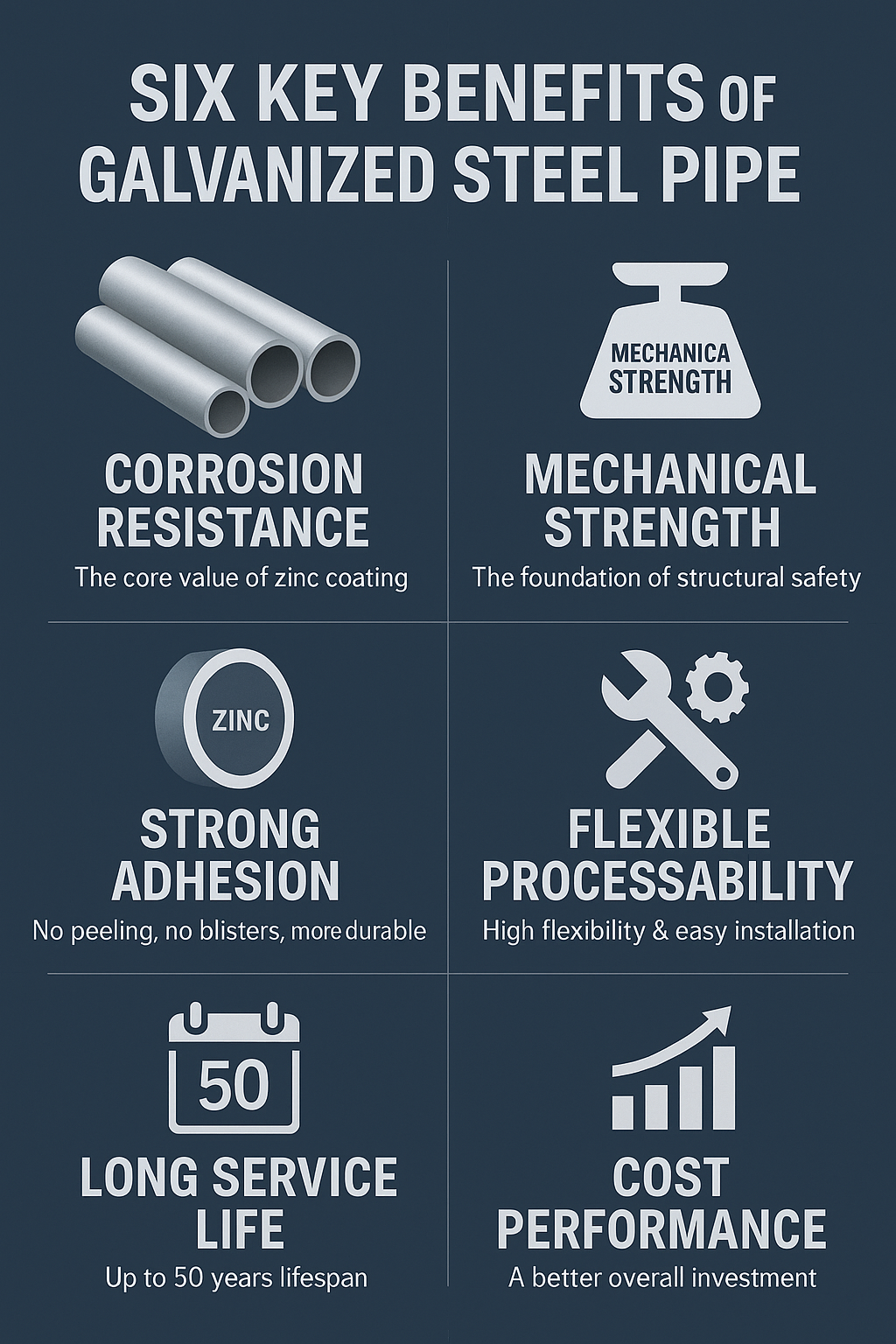

The Six Key Performance Characteristics of Galvanized Steel Pipes

1.Corrosion Resistance: The Core Value of the Galvanized Layer

The primary performance advantage of galvanized steel pipes lies in their corrosion resistance. The zinc layer itself possesses excellent antioxidant properties. When exposed to humid or corrosive environments, the zinc layer reacts preferentially with oxygen, water, acids, and alkalis, thereby protecting the underlying carbon steel structure from oxidation.

Hot-dip galvanized zinc layers typically have a thickness of 35–100 microns, providing long-term outdoor protection and a service life of 20 years or more;

Electrogalvanized zinc layers typically have a thickness of 5–30 microns, suitable for indoor or low-corrosive environments.

Conclusion: In harsh environments (such as coastal areas, humid factories, or outdoor structures), hot-dip galvanized products should be prioritized.

| Characteristics | Description |

| Long-term protection | Maintains corrosion resistance for 10 to 30 years in harsh environments such as industrial, coastal, and humid-hot conditions |

| Low maintenance costs | No need for frequent painting or coating repairs |

| Strong structural protection | Prevents issues such as pipe wall thinning, leaks, and structural instability caused by corrosion |

| Wide adaptability | Suitable for various applications including water supply and drainage, bridges, railings, and pipe supports |

2.Stable mechanical strength: The fundamental guarantee of structural safety

The strength of galvanized steel pipes primarily stems from their internal carbon steel substrate, which typically uses structural carbon steels such as Q195, Q235, or Q345. These materials possess excellent tensile strength, compressive strength, and impact resistance, capable of meeting various structural or pressure requirements.

| Performance Indicators | Typical Values | Description |

| Tensile Strength | ≥ 350 MPa | Ability to resist tensile forces |

| Yield strength | ≥ 235 MPa | Maximum stress before permanent deformation |

| Elongation | ≥ 20% | Indicates material plasticity |

| Impact toughness | Excellent | Can absorb impact energy without fracturing |

| Hardness | HB 120–180 | Indicates resistance to compression or wear |

High load-bearing capacity — performs stably in applications such as high-rise buildings, water supply systems, and scaffolding

Resistance to deformation — does not easily bend, deform, or fracture under long-term pressure

Good fatigue resistance — does not easily develop micro-cracks or fatigue damage under long-term loading

Secure connections — easy to weld or thread connect, with strong structural integrity

3.Strongly adherent zinc coating: does not peel off, more durable

Unlike surface treatments such as painting or spraying, the hot-dip galvanizing process forms a Zn-Fe alloy layer at high temperatures, achieving a metallurgical bond between the zinc coating and the steel substrate. This bonding method is extremely robust, and the strongly adherent zinc coating is unlikely to peel off, bubble, or delaminate during use, providing long-lasting corrosion protection.

Longer-lasting corrosion protection — the zinc layer does not peel off, providing continuous protection for the steel pipe substrate

Safer transportation and installation — no damage to the zinc layer caused by handling or cutting

Better resistance to climatic influences — does not blister or peel off under alternating hot and cold conditions, rain, snow, or humid heat

Extended product lifespan — reduces maintenance and replacement costs in the long term

4.Excellent processing adaptability: high flexibility and convenient construction

Galvanized steel pipes often require cutting, welding, and other processing during construction. Their excellent processing ductility and weldability enable efficient construction operations, reduce material consumption, meet complex welding requirements, and adapt to various installation environments, thereby shortening construction cycles and reducing construction costs.

5.Exceptional service life and low maintenance costs

Due to the high corrosion resistance and adhesion strength of the zinc coating, it remains stable even in harsh outdoor environments such as acid rain. Therefore, frequent painting or rust removal is unnecessary, reducing labor inspection frequency and costs. Equipment and structural systems operate stably for longer periods, ensuring system continuity and safety.

| Application Environment | Service Life (Reference) |

| Indoor Dry Environment | Over 40–50 years |

| General Outdoor Environment | 20–30 years |

| Coastal/Industrial Corrosion Zones | 10–20 years (depending on specific protective treatment) |

6.Outstanding Cost-Effectiveness: Optimal Overall Cost

| Advantages | Cost-Saving Points |

| No Coating Treatment Required | No need for additional anti-corrosion painting or epoxy coating |

| High Construction Efficiency | Reduces labor hours and costs |

| Universal Connection Methods | Threaded/welded fittings are universal, reducing the need for custom fittings |

| Long Maintenance Cycle | No major repairs or frequent replacements required over the years |

| Moderate Material Costs | Significantly more cost-effective than stainless steel or copper pipes |

Key Performance Characteristics and Typical Application Scenarios

| Performance Characteristics | Corresponding Typical Application Scenarios |

| High Corrosion Resistance | Agricultural irrigation, coastal buildings, cable trays, wastewater treatment pipelines |

| High Strength | Scaffolding, photovoltaic supports, curtain wall frameworks, ceiling grid systems |

| Strong Adhesion | Guardrails, traffic barriers, fence foundation fittings |

| Flexible Processing | Residential wiring conduits, ventilation systems, HVAC supports |

| Durable and Low Maintenance | Municipal pipelines, communication facilities, warehousing systems |

Summary: The value behind performance—one pipe, multiple functions, comprehensively addressing engineering challenges

Galvanized steel pipes, with their corrosion resistance, pressure-bearing capacity, durability, cost-effectiveness, and ease of construction, have become an indispensable material in numerous engineering fields. From infrastructure to agricultural supports, from building frameworks to power and communication systems, they consistently deliver stable performance to enhance engineering efficiency, reduce costs, and improve effectiveness.