As one of the most widely used pipe materials in industrial applications and infrastructure construction, carbon steel pipes are favored by industries such as construction, energy, and chemicals due to their stable performance and cost-effective characteristics. Carbon steel pipes serve multiple functions, including support, transportation, and connection, and can be found in various applications such as municipal water supply and drainage systems, factory ventilation pipelines, building structures, and agricultural greenhouse frameworks. While carbon steel pipes are widely used, public awareness of their proper use remains lagging, leading to frequent misconceptions that result in increased costs, risks, and losses.

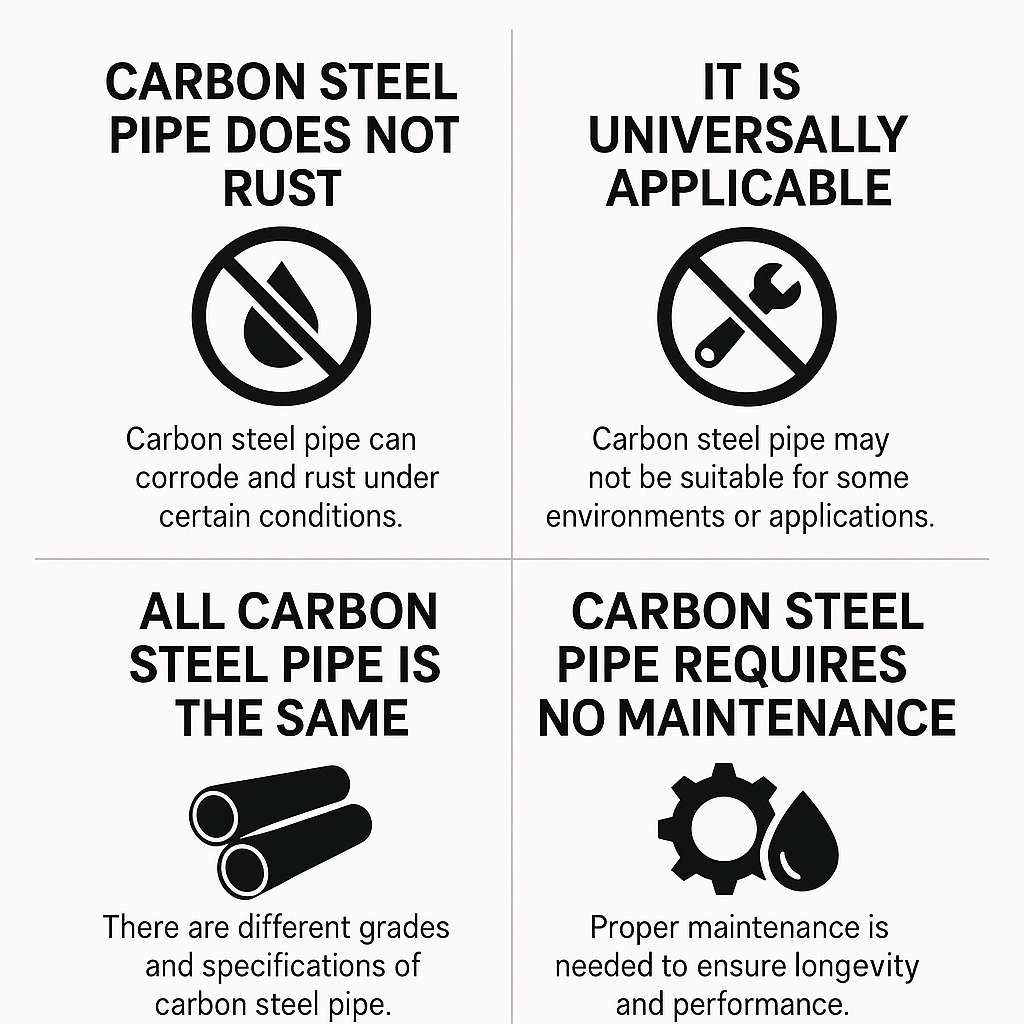

Misconception 1: Carbon steel pipes do not rust and can be used uncovered for extended periods.

【Common applications】: Outdoor steel structures and pipeline systems, internal facilities in industrial plants, buried/underwater engineering projects, temporary engineering facilities,non-load-bearing auxiliary components

Many users view “steel pipes” as synonymous with “durable and robust,” believing they require no additional protection. However, carbon steel inherently rusts easily in humid, acidic, alkaline, or salt fog environments, especially bare black pipes (without galvanization or coating treatment), which may develop oxidation layers or rust spots within months.

【Recommendation】:

For projects in outdoor or humid environments, we recommend using hot-dip galvanized pipes or coated corrosion-resistant pipes.

For temporary structures, we also recommend applying a simple coat of anti-rust paint to extend their lifespan.

Pipelines in direct contact with water, gas, or liquids must strictly consider corrosion protection processes.

Misconception 2: All carbon steel pipes can be used interchangeably

【Common in】: Pressure pipeline systems, low-temperature applications, budget-constrained projects, non-professional procurement or construction parties

Many clients directly refer to “carbon steel pipes” or “steel pipes” in tenders or procurement, ignoring the specific application differences between products. For example, structural pipes (such as scaffolding) and fluid conveyance pipes have significant differences in standards, wall thickness, and tolerances. If structural pipes are mistakenly used in water supply systems, it not only poses a leakage risk but may also threaten usage safety.

【Recommendations】:

Clearly define the engineering design purpose and select the corresponding standards.

Communicate with supplier technical personnel to confirm that the application and selection are matched.

Establish a scientific material management system, implement strict process control, and actively apply new technologies to effectively mitigate quality risks associated with the arbitrary interchangeability of carbon steel pipes.

Misconception 3: Galvanized pipes are “maintenance-free” and require no upkeep

【Common in】: Building plumbing systems, outdoor structures (guardrails, scaffolding), industrial pipelines (chemical, HVAC), temporary projects (construction site temporary water pipes, support frames)

Many people mistakenly believe that the “galvanized coating” of galvanized pipes ensures permanent corrosion resistance, leading to neglect of post-installation inspections and maintenance. However, the galvanized coating gradually wears away over time and degrades more rapidly under strong acid/alkali conditions or when damaged. Especially if welded joints are not properly protected, they are more likely to become “potential hazards.”

【Recommendations】:

In acidic or alkaline environments, use hot-dip galvanized pipes or epoxy composite pipes with thicker coatings.

After pipe installation, apply zinc coating or paint to welded joints.

Regularly inspect the surface for early signs such as rust spots, blisters, or cracks.

Misconception 4: Carbon steel pipe quality is judged solely by appearance and price

【Common in】: Small-scale projects, rushed schedules, and trade intermediary procurement

The key factors determining carbon steel pipe performance lie in its “internal qualities”—material composition, weld quality, wall thickness consistency, etc.

【Recommendation】:

Purchase products from manufacturers with production qualifications and compliant with standards. Verify product factory inspection certificates, material reports, and conduct third-party sampling inspections when necessary to ensure quality compliance.

For long-term cooperation projects, it is recommended to choose brand manufacturers or original manufacturers to ensure consistency.

Misconception 5: Thicker carbon steel pipes are better

【Common in】: Overdesigned projects, decisions made by non-professional construction companies

Some customers, out of caution, blindly pursue thicker pipe walls, mistakenly believing that “thicker means stronger.” However, in reality, overly thick carbon steel pipes not only significantly increase costs but also add burdens to transportation, welding, and supports, thereby impairing construction efficiency.

More seriously, blindly increasing thickness may overlook actual engineering parameters such as system pressure, flow rate, and temperature changes, leading to design deviations.

【Recommendation】:

Select appropriate wall thickness based on design pressure and standard specifications.

in low-pressure transportation and non-pressure-bearing structures, lightweight carbon steel pipes fully meet usage requirement.

maintain communication with design institutes or construction units to scientifically select types and avoid resource waste.

Misconception 6: Carbon steel pipes can be ignored once installed

【Common in】: Municipal underground pipelines, old building renovations, rural water pipe projects.

Some projects lack a follow-up management system after completion, especially pipeline systems that are “buried underground or pass through walls,” which are more likely to be overlooked. However, carbon steel pipe systems often face dynamic risks such as settlement deformation, joint loosening, water hammer impact, and corrosion perforation. Without timely intervention, this may result in significant losses.

【Recommendations】:

Establish a pipeline inspection plan, focusing on critical areas such as welds and elbows.

For buried systems, consider adding casings or warning signs to reduce maintenance complexity.

Establish a lifecycle archive, including installation drawings, material records, and maintenance logs, to provide a basis for future replacements.

Conclusion: Use carbon steel pipes scientifically to truly unlock their value.