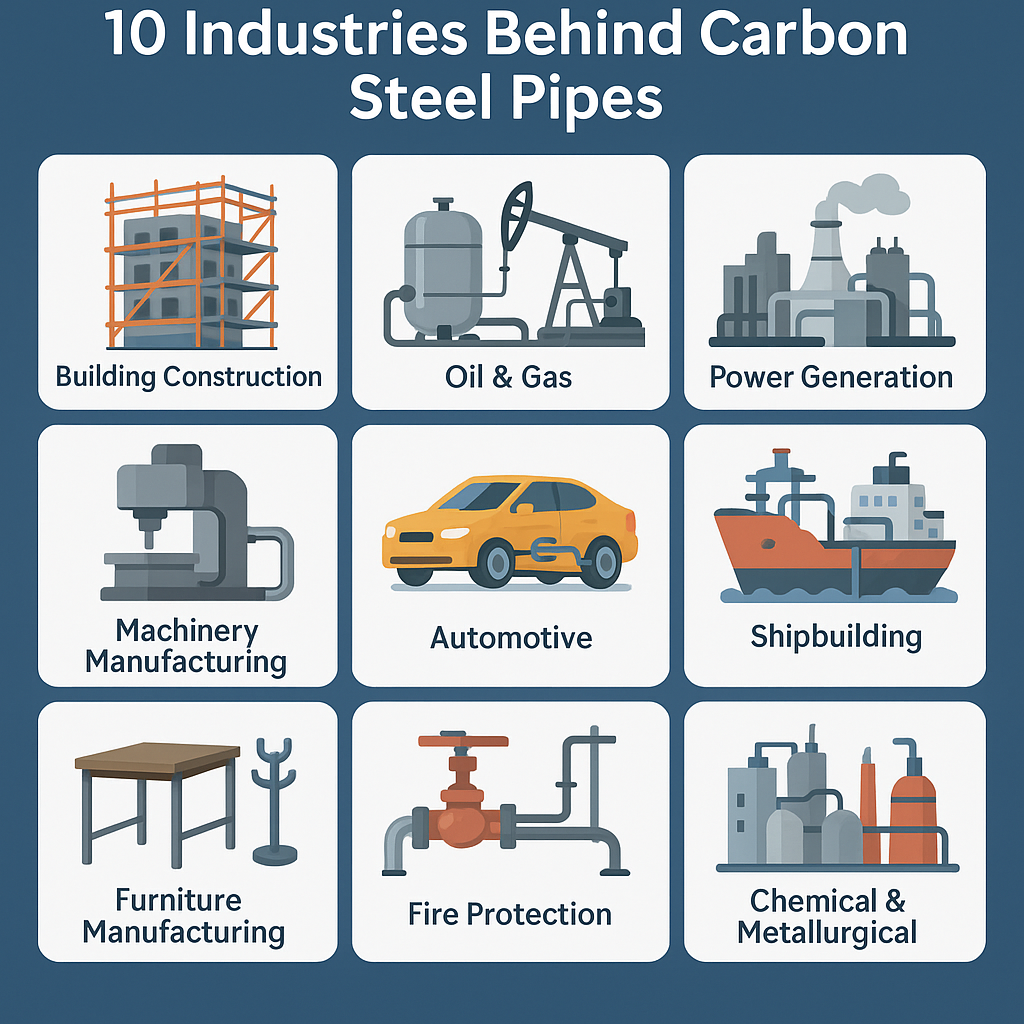

In our daily lives and industrial production, there is a material that is “invisible yet indispensable”—carbon steel pipes. Whether in the skyscrapers of bustling cities, the relentless flow of oil pipelines, or even the industrial-style coffee table on your balcony, it plays a silent yet critically important role.

As a carbon steel pipe manufacturer, we aim to provide this article from a consumer’s perspective, using simple and concrete examples to illustrate how carbon steel pipes function as the “steel backbone” across 10 key industries, helping you make more informed decisions regarding material selection, application, and collaboration.

1.Construction Industry: The taller the building, the more important the pipes

Have you ever seen a construction site under construction? Steel pipe scaffolding, grid-like structural frameworks, and temporary walkway supports—these almost all rely on carbon steel pipes.

Why choose it?

High strength, capable of supporting large-scale building loads;

Easy to process, with convenient welding and installation;

Cost-effective, suitable for large-scale use

If you are a client involved in construction or engineering contracting, selecting carbon steel pipes with appropriate specifications and surface treatments (such as hot-dip galvanizing for corrosion resistance) can enhance construction safety and reduce maintenance costs.

2.Oil and Gas Industry: The “Main Arteries” Ensuring Energy Flow

Every drop of gasoline you see is supported by steel pipes spanning thousands of kilometers.

Carbon steel pipes in the oil and gas sector are responsible for transporting crude oil, natural gas, and refined petroleum products.

Why choose it?

Capable of withstanding high pressure and temperature;

Corrosion-resistant coatings can be applied to both the interior and exterior of the pipes;

Certified by international standards such as API, suitable for global oil and gas projects.

If you are an engineering or procurement manager at an energy-related company, selecting the right carbon steel pipe material and corrosion protection solution is the first step in ensuring safe oil and gas transportation and reducing leakage risks.

3.Power Industry: Making Thermal Energy Conversion Safer and More Efficient

Carbon steel pipes are primarily used in power plants for boilers, turbines, and high-temperature steam systems. They withstand temperatures of several hundred degrees Celsius and pressures of dozens of atmospheres.

Reasons for selection:

Specialized seamless steel pipe materials for high-temperature and high-pressure applications;

Thick walls for enhanced durability;

Supports high-precision component welding, suitable for precision equipment integration.

If you are a power plant construction contractor, selecting carbon steel pipes compliant with national and power plant standards is a critical step for project acceptance.

4.Mechanical Manufacturing: A Single Pipe Forms the Skeleton of a Machine

From agricultural machinery to engineering vehicles, from automated equipment to mining conveyors, carbon steel pipes are fundamental components in mechanical systems.

Features:

Can be used as supports, arms, drive shafts, etc.;

High precision, suitable for secondary processing;

Stable material properties, capable of withstanding repeated stress and vibration.

If you are a mechanical manufacturing plant or design company, selecting carbon steel pipes with appropriate wall thickness and good processing performance not only enhances product strength but also improves assembly efficiency.

5.Automotive Industry: More Than Just “Exhaust Pipes”

You may know that metal tubes are used in exhaust systems. However, carbon steel tubes are also used in automotive chassis frames, body support structures, and even electric vehicle battery trays.

Why is this important?

Combines strength and toughness;

Compatible with welding processes such as spot welding and laser welding;

Customizable non-standard cross-sections (square, elliptical, etc.).

For automotive parts manufacturers, lightweight and high-strength carbon steel tubes are an ideal choice for enhancing product performance and safety.

6.Shipbuilding and Offshore Engineering: Withstanding the Test of Sea Winds and Waves

On large ships, carbon steel tubes are primarily used in fluid transportation systems for fuel, water, and air, as well as for ship hull structural support.

Advantages:

Strong corrosion resistance (thickened coating or corrosion-resistant layer);

Large diameter and thick walls for load-bearing capacity;

Compliant with classification society certifications (CCS, DNV, etc.).

If you are a shipyard, port construction company, or offshore engineering project entity, choosing certified marine-grade carbon steel pipes ensures reliable long-term operation of equipment in complex marine environments.

7.Furniture Manufacturing: A Cross-Industry Transition from Industrial to Aesthetic

Did you know? That metal bookshelf, balcony coffee table, or coat rack in your home might be made from carbon steel pipes.

Features of carbon steel pipes for furniture:

Aesthetically pleasing appearance with clean lines, suitable for industrial-style designs;

Customizable surface finishes (black sand, electroplated silver, brass-like finishes, etc.);

Can be customized into elliptical tubes, flat-oval tubes, or special-shaped tubes.

If you are a home furnishings brand, designer, or display rack manufacturer, using carbon steel pipes for creative furniture not only ensures durability but also offers a unique style, giving you a competitive edge in the market.

8.Fire Protection Systems: Delivering Lifesaving Water in Critical Moments

Whether in commercial buildings, residential areas, or industrial parks, carbon steel pipes serve as the “lifeline” for fire sprinkler systems.

Key points for fire protection steel pipes:

High pressure-bearing capacity;

Surface coated with red paint or galvanized for corrosion resistance and rust prevention;

Compliant with national fire safety standards, facilitating inspection and acceptance.

As a property management company, fire safety installation contractor, or design firm, selecting fire safety pipes that meet standards is a demonstration of safety responsibility.

9.Municipal and Infrastructure: The “venous network” hidden beneath the city

Behind urban water supply, drainage, heating, and gas infrastructure lies a vast network of carbon steel pipes.

Requirements:

Large diameter with thick walls;

Rigorous internal and external corrosion protection;

Customizable joint configurations for convenient on-site connections.

If you are a municipal project contractor, or gas company, the appropriate pipe specifications and supply capacity directly impact the project schedule and operational performance.

10.Chemical and Metallurgy: Extreme Operating Conditions

In chemical plants, steel mills, and smelting workshops, carbon steel pipes handle corrosive liquids, high-temperature gases, or powdered raw materials.

Special requirements:

Alloy steel or special materials for enhanced performance;

Internal lining (e.g.PTFE) or special coatings required;

Precise control of wall thickness and tolerances.

As a chemical equipment company, pipeline installer, or project contractor, selecting a partner capable of customizing high-performance carbon steel pipes will effectively reduce maintenance frequency and safety risks.

Conclusion: Carbon steel pipes are not just “steel”; they are the “skeleton” connecting our industrial world.

The story of a carbon steel pipe is not just about how it is welded, coated, or transported, but also about how it enables oil to flow, buildings to stand, hot water to be supplied, and furniture to be aesthetically pleasing. It is hidden in every corner of urban underground spaces, factory workshops, and residential areas, an indispensable part of modern life and production.

As a steel pipe manufacturing company, we not only focus on the product itself but also aim to help every customer, partner, and user understand its true purpose and potential value.