1. Key Technical Parameters

1.1 Base Material Standards

- ASTM A653 (US) / EN 10346 (EU) / JIS G3302 (Japan)

- Common grades: DX51D, DX52D, DX53D (formability grades)

- Thickness range: 0.3mm to 5.0mm (±0.05mm tolerance)

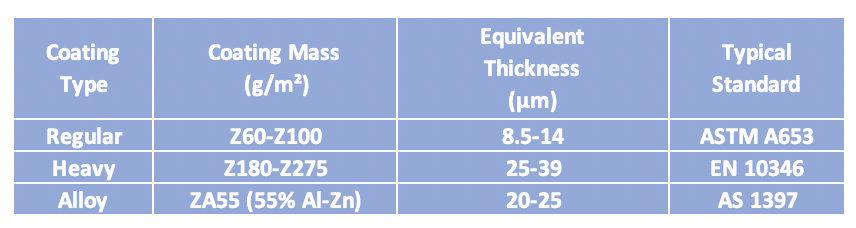

1.2 Zinc Coating Specifications

1.3 Mechanical Properties

- Tensile strength: 270-500 MPa (varies by grade)

- Elongation: 18%-40% (DX53D for deep drawing)

- Spangle size: Regular (60-150µm) / Minimal spangle (≤30µm)

2. Application Case Studies

2.1 Automotive Industry (Tesla Cybertruck)

- Material: Galvanized Ultra-Hard 30X Cold-rolled Steel

- Coating: ZM310 (Zn-Mg-Al alloy, 3.1µm)

- Performance: Withstands 9mm bullet impact + 10,000hr salt spray test

2.2 Green Buildings (Shanghai Tower)

- Application: Curtain wall substrates

- Specs: DX54D+Z275, 0.7mm thickness

- Advantage: 50-year maintenance-free facade vs. 15-year painted steel

2.3 Renewable Energy (NextEra Solar Farm)

- Component: Mounting structure

- Material: Magnelis® (Zn-3.5%Mg-2%Al)

- Result: 0.003mm/year corrosion rate in coastal Florida

3. Selection Guidelines

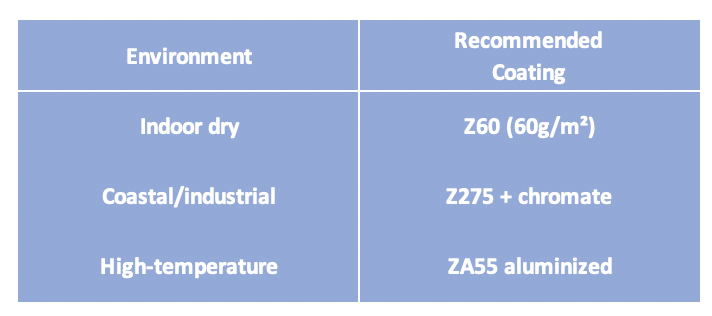

3.1 Environment-Based Coating Choice

3.2 Cost-Performance Analysis

- Z60: $0.35/kg (general purpose)

- Z275: $0.52/kg (10x lifespan in harsh environments)

- ZA55: $0.68/kg (30% lighter than equivalent protection)