Introduction

Square tubes are widely used in construction, manufacturing, automotive, and engineering industries due to their structural strength and versatility. The two primary manufacturing methods for square tubes are **hot rolling** and **cold rolling**, each offering distinct properties and advantages. This article explores the differences between hot-rolled and cold-rolled square tubes, their production processes, and their applications.

1. Hot Rolled Square Tubes

Production Process

Hot rolling involves shaping steel at high temperatures (typically above 1,700°F or 927°C). The process includes:

1. Heating steel billets or slabs to a malleable state.

2. Passing the material through rollers to form square tubes.

3. Cooling the tubes, which may result in slight dimensional variations.

Characteristics

– Surface Finish**: Slightly rough with mill scale (oxide layer).

– Dimensional Tolerance**: Less precise due to thermal expansion and contraction.

– Mechanical Properties**: Improved ductility and toughness but lower strength compared to cold-rolled tubes.

– Residual Stresses**: Minimal internal stress due to high-temperature processing.

Applications

Hot-rolled square tubes are commonly used in:

– Structural frameworks (buildings, bridges)

– Heavy machinery and equipment

– Railway and transportation infrastructure

2. Cold Rolled Square Tubes

Production Process

Cold rolling is performed at or near room temperature and involves:

1. Starting with hot-rolled steel, which is further processed.

2. Passing the material through rollers to achieve precise dimensions.

3. Additional treatments (annealing, galvanizing) may be applied for enhanced properties.

### **Characteristics**

– **Surface Finish**: Smooth and free from mill scale.

– **Dimensional Tolerance**: Highly precise with tighter tolerances.

– **Mechanical Properties**: Higher strength and hardness but reduced ductility.

– **Residual Stresses**: May have internal stresses requiring stress-relief annealing.

Applications

Cold-rolled square tubes are ideal for:

– Automotive and aerospace components

– Furniture and decorative structures

– Precision machinery and hydraulic systems

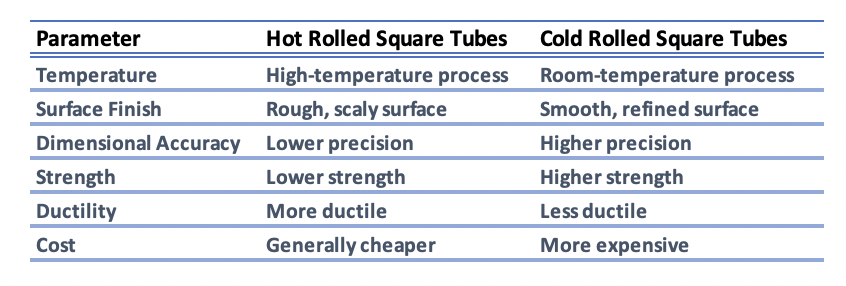

3. Key Differences Between Hot Rolled and Cold Rolled Square Tubes

Understanding these differences ensures optimal material selection for engineering and construction needs.

sqaure steel pipe

square tube

square steel tube