Stainless steel pipe sandblasting is the process of cleaning and roughening the substrate surface through the impact of high-speed sand flow. Powered by compressed air, a high-speed spray beam is formed and the spraying material (copper ore, quartz sand, silicon carbide, iron sand, Hainan sand) is sprayed at high speed onto the surface of the workpiece to be treated, so that the appearance or shape of the outer surface of the workpiece surface is changed. Due to the impact and cutting effect of the abrasive on the surface of the workpiece, give the workpiece surface a certain degree of cleanliness and different roughness, improve the mechanical properties of the workpiece surface, thus improving the fatigue resistance of the workpiece and increasing the distance between the workpiece and the coating.

The pretreatment stage of the stainless steel pipe blasting process refers to the treatment that should be carried out before the surface of the workpiece is coated and sprayed with a protective layer. The quality of sandblasting pretreatment affects the adhesion, appearance, moisture resistance and corrosion resistance of the coating. If the pre-treatment is not done properly, corrosion will continue to spread under the coating, causing it to peel off in sheets. After careful cleaning, the coating life of a surface can be 4-5 times longer than that of a workpiece that is typically cleaned simply by exposure. There are many methods of surface cleaning, but the most commonly accepted methods are:solvent cleaning, acid cleaning, hand tools and power tools.

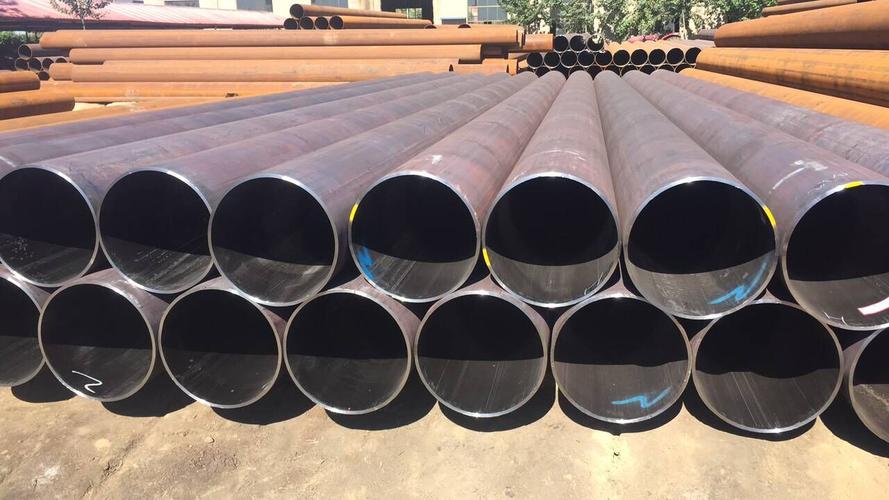

Stainless steel pipe spray sand related knowledge introduction

Stainless steel pipe spray sand is the use of compressed air flow in the steel pipe surface spray quartz sand. Sandblasting for cleaning or finishing the surface can be divided into dry sandblasting and wet sandblasting. The purpose of sandblasting: to remove the castings, forgings or heat treatment stainless steel tube surface of the type of sand and oxide skin. Remove rust, carbon and weld slag on the surface of the stainless steel tube. Improve the surface roughness of the stainless steel tube, so as to improve the bonding force of its back cover foot. Remove burrs and directional wear marks on both ends of stainless steel tubes. Darken the surface of the stainless steel tube.

Preparation work before dry sandblasting. Stainless steel tube with oil on the surface should be degreased before sandblasting and then dried. Because the surface greasy or wet affects the sandblasting effect. However, the most widely used abrasive is cleaned and screened quartz sand, especially because of its low price and easy access. According to the reference standard of the wall thickness of the stainless steel tube to be sandblasted, the compressed air should be at a suitable pressure, the pressure should be in the range of 0.5 ~ 0.1 MPa, and the compressed air should be free of oil and water.